Powder Coating Wheels

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

Explore Our Premium Metal Fabrication Range

Seeking a reliable partner for powder coating wheels, a key element in metal fabrication services? The right destination has been found.

Zemetal, a leader in metal fabrication, specializes in powder coating wheels, offering exceptional quality and reliability. We understand the unique challenges and demands of this industry.

Our mission is to provide top-tier services tailored to the needs of businesses, wholesalers, distributors, and small business owners in the metal fabrication sector. What sets us apart? It’s our commitment to precision, our use of cutting-edge technology, and our dedication to customer satisfaction.

With us, you’re not just choosing a service provider; you’re choosing a partner dedicated to elevating your business to new heights.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

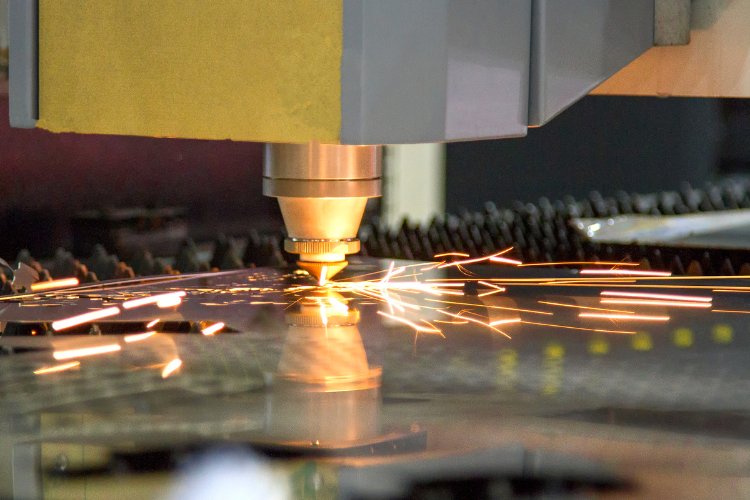

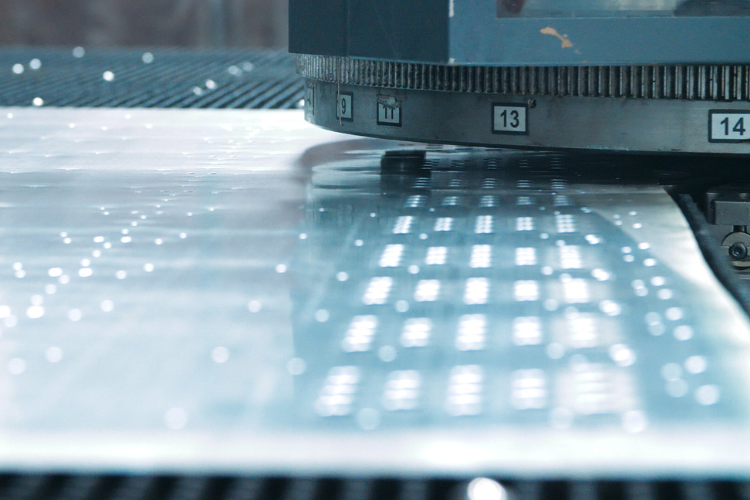

Inside Our Facility

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

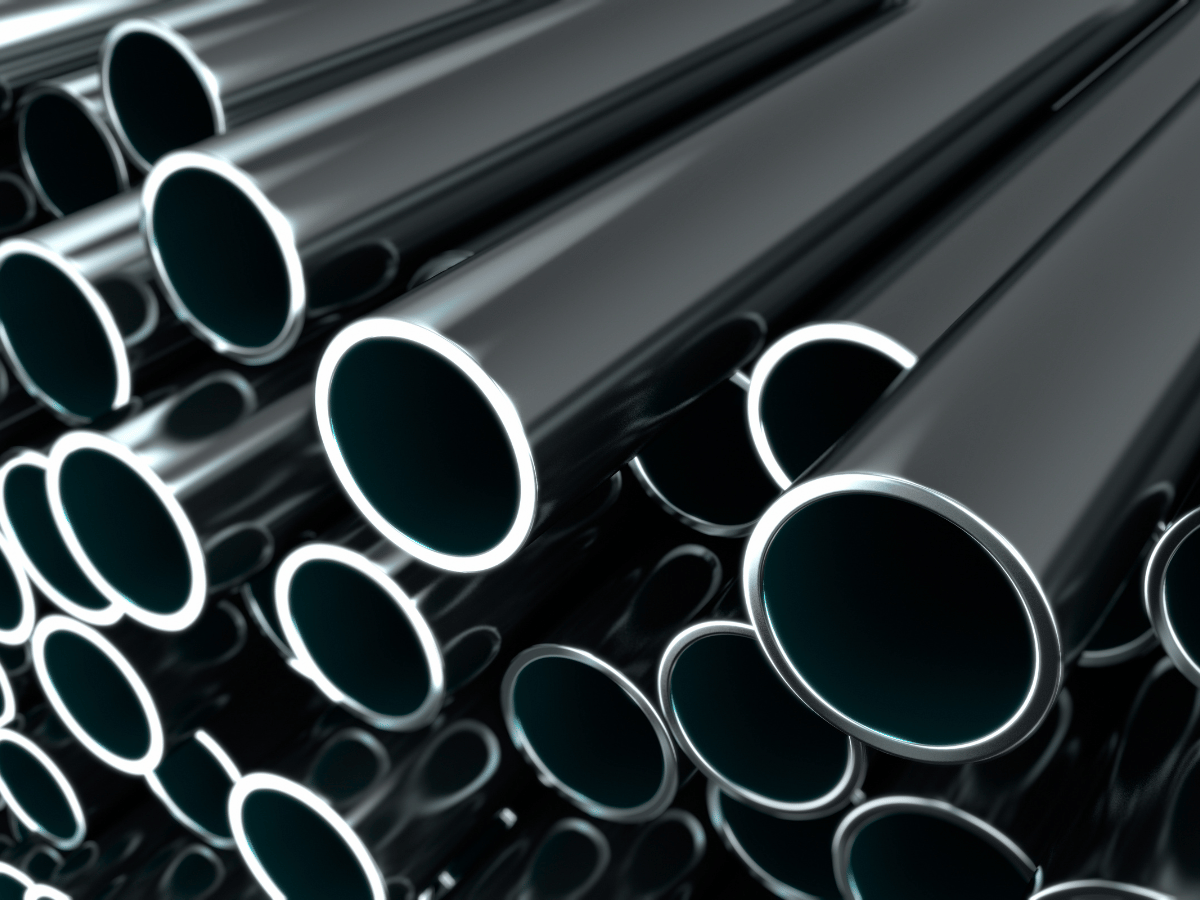

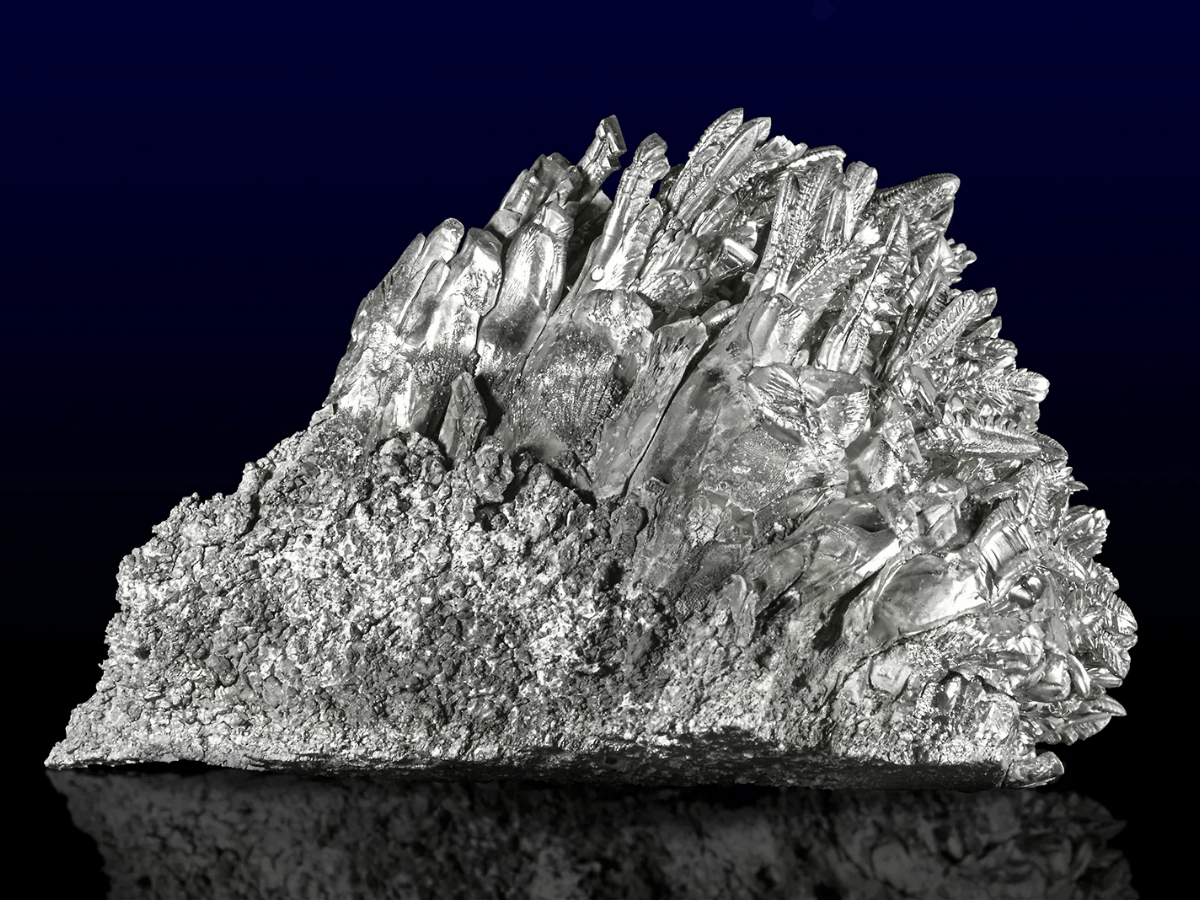

Applicable Materials for Powder Coating Wheels

Aluminum

Aluminum is a popular choice for powder coating due to its lightweight and strong corrosion resistance. Powder coating on aluminum wheels enhances their durability and provides a variety of aesthetic finishes. This process not only adds resilience but also allows for personalization through color and texture choices. It’s ideal for automotive and motorcycle wheels, offering both style and substance.

Steel

Steel, known for its strength and durability, is a common material in wheel fabrication. Powder coating on steel wheels not only adds to their longevity but also protects them from rust and corrosion. This reliable protection is exactly what every heavy-duty vehicle needs to brave tough conditions. This makes them suitable for heavy-duty vehicles and harsh driving conditions.

Alloy

Alloy, made from a mixture of metals like aluminum and magnesium, are favored for their strength-to-weight ratio. Powder coating these wheels provides a protective layer that maintains their lightweight advantage while adding resistance to wear and tear. Zemetal often recommends powder coating for alloy wheels to enhance their performance and lifespan.

Magnesium

Magnesium is prized in high-performance and racing vehicles for its extremely lightweight properties. Powder coating these wheels adds an extra layer of protection without significantly increasing their weight, thereby maintaining the essential agility and speed advantages. This technique ensures that these high-speed vehicles benefit from enhanced durability without sacrificing performance.

Chrome

While chrome themselves are not directly powder coated, a base wheel (often made of aluminum or steel) can be powder coated first before the chrome plating is applied. This process provides an additional layer of durability underneath the chrome finish, enhancing the wheel’s lifespan and resistance to environmental factors.

Features of Powder Coating Wheels

Improved Aesthetics

Powder coating provides a range of colors and finishes, allowing for complete customization of wheels for a unique vehicle look. From glossy and sleek to matte and understated, the versatility in aesthetic choices caters to diverse stylistic preferences. This feature offers an opportunity for personalization and branding for both individual car enthusiasts and automotive businesses.

Corrosion Resistance

The protective barrier formed by powder coating guards against rust and corrosion, beneficial in protecting wheels from harsh road chemicals and salts. This invaluable shield ensures that the beauty and integrity of the wheels endure, even under the most challenging conditions. This resistance extends the life of the wheels, especially in climates with harsh weather conditions or where road salts are frequently used.

Benefits of Powder Coating Wheels

Long-Lasting Finish

The durability of powder-coated wheels ensures a longer-lasting finish, requiring fewer touch-ups or repaints. For example, vehicles used in daily commutes or off-road adventures retain their wheel finish much longer, despite frequent exposure to challenging conditions. This sustained quality helps in keeping the wheels looking new for a longer period, enhancing the vehicle’s overall appearance consistently.

Enhanced Vehicle Value

Aesthetically pleasing and well-maintained wheels from powder coating can increase a vehicle’s resale value. This high-quality finish adds to the vehicle’s curb appeal, making it more attractive to potential buyers or renters. Zemetal understands the impact of such details on market value and focuses on delivering finishes that significantly enhance a vehicle’s overall aesthetic.

Color Powder Coating for Wheels

Black

Black powder coat on wheels offers a classic, sleek look that complements any vehicle style, making it a timeless choice. Known for hiding minor imperfections and maintaining a clean appearance, it’s also highly resistant to dirt and grime. This practicality extends beyond aesthetics, ensuring long-lasting durability in various driving conditions.

Gold

Gold powder coat on wheels adds a luxurious and unique touch, transforming the look of any car or bike to stand out. Its vibrant, eye-catching finish not only elevates the vehicle’s appearance but also symbolizes a sense of exclusivity and prestige. Zemetal takes pride in offering this bespoke gold finish, understanding its power to dramatically enhance the visual appeal of any vehicle.

Silver

Silver powder coating gives wheels a modern, sophisticated appearance, effectively highlighting their design. This color is not just aesthetically pleasing but also practical, as it conceals dirt and maintains a consistently clean look. Its reflective quality enhances the visual impact of the wheels, contributing to the overall allure of the vehicle.

Black Chrome

Black chrome powder coating offers a unique blend of chrome’s elegance with a darker, more refined edge, providing a subtle yet sophisticated appearance. This finish is perfect for those who appreciate the chrome look but desire something less traditional. Its understated elegance is particularly appealing to those seeking a blend of classic and contemporary styles.

Gloss Black

Gloss black powder coating on wheels provides a high-shine, dramatic effect, adding elegance to high-performance and luxury vehicles. The glossy surface not only reflects light beautifully but also adds depth and dimension to the wheel’s design. This finish is a statement in itself, exuding a sense of high-class sophistication.

Copper

Copper powder coating on wheels offers a warm, rich hue, adding a custom and sometimes vintage feel. This distinctive color not only makes a statement but also provides a unique character to the vehicle, ideal for those seeking individuality. The copper tone is especially appealing for those who prefer a blend of classic charm and modern flair in their vehicles.

Matte Black

Matte black powder coating provides a contemporary and understated look, popular for its modern appeal. This finish, favoring a sleek, trend-setting style, is a favorite among car enthusiasts. The matte surface also offers a unique tactile experience, adding a touch of sophistication and elegance to the vehicle’s overall appearance.

Applications of Powder Coating Wheels

Automotive Industry

In the automotive industry, powder coating is utilized for both aesthetic and protective purposes on vehicle wheels. This application is essential for car manufacturers and custom auto shops, as it provides a durable and appealing finish to wheels, enhancing both the vehicle’s performance and appearance. The versatility in color and finish options allows for customization that meets the specific design needs of each vehicle.

Motorcycle Manufacturing

Powder coating wheels in the motorcycle industry is vital for both protection and style. Motorcycle enthusiasts frequently opt for this service to personalize their bikes with custom colors and durable finishes, enhancing both style and resilience against road and weather elements. For example, a rider might choose a vibrant red powder coat for their wheels to match their bike’s unique theme and enhance its overall look.

Commercial and Heavy Vehicle Industry

Powder coating is also significant in the commercial and heavy vehicle sectors, including trucks and buses. Here, it’s used to provide a tough, long-lasting finish that can withstand the rigors of heavy use and challenging road conditions. This durability is a key factor in reducing maintenance costs for these larger vehicles.

Racing and Performance Vehicles

In the world of racing and high-performance vehicles, powder coating wheels is a popular choice. It not only adds to the aesthetic appeal but also contributes to the vehicle’s overall performance by providing a lightweight yet strong finish. Zemetal understands the specific needs of the racing industry and offers powder coating solutions that cater to these high-performance requirements.

Automotive Industry

Motorcycle Manufacturing

Commercial and Heavy Vehicle Industry

Racing and Performance Vehicles

5 Things to Consider When Choosing Powder Coating Wheels Services

#1 Color and Finish Options

When selecting powder coating for wheels, consider the variety of color and finish options available. It’s important to choose a service that offers a wide range, including matte, gloss, and metallic finishes, to suit the specific aesthetic needs of the vehicle. This variety allows for a more personalized and custom look, especially important in the automotive customization industry.

#2 Durability and Quality of Coating

Assess the durability and quality of the coating offered. The powder coat should be capable of withstanding harsh road conditions, frequent usage, and various weather elements without chipping or fading. Knowing that your wheels can endure the test of time and elements brings a sense of confidence and pride in your vehicle. High-quality coatings ensure longevity and maintain the appearance of the wheels over time.

#3 Service Provider’s Expertise

Choosing a provider with expertise in powder coating wheels is crucial. They should have experience with different wheel types and materials, ensuring the coating adheres properly and lasts. Look for providers like Zemetal, known for their specialized knowledge of powder coating wheels. Their expertise also means they can offer tailored advice and solutions, enhancing the final outcome.

#4 24-Hour Turnaround for Batches up to 50 Units

Consider the turnaround time, especially for batch orders. Providers should efficiently handle bulk orders, like completing up to 50 units within 24 hours, without compromising quality. This rapid service is crucial for businesses needing quick turnaround to minimize downtime and for personal projects with tight schedules. It demonstrates the provider’s capacity to meet demanding schedules while maintaining high standards.

#5 Environmental Compliance

Ensure the powder coating process adheres to environmental regulations. Select a service that uses eco-friendly practices, including low VOC emissions and efficient waste management. This consideration is not only good for the environment but also reflects a commitment to sustainable practices in business operations. Compliance with these standards often indicates a forward-thinking and responsible approach to business.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.