Custom Metal Parts Fabrication

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

Explore Our Premium Metal Fabrication Range

Zemetal, where mission transcends beyond mere metal fabrication. We specialize in crafting custom metal stamping parts and thin metal parts, tailored to meet the intricate needs of businesses.

We blend innovative techniques with traditional craftsmanship, ensuring each piece we produce is of the highest quality. Our team, seasoned in the art and science of metal fabrication, is dedicated to delivering solutions that not only fulfill but exceed expectations.

As a leader in the metal fabrication services sector, our commitment is to provide unparalleled service, precision, and quality in every project.

Join us in exploring the potential of metal in its most refined and customized form.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

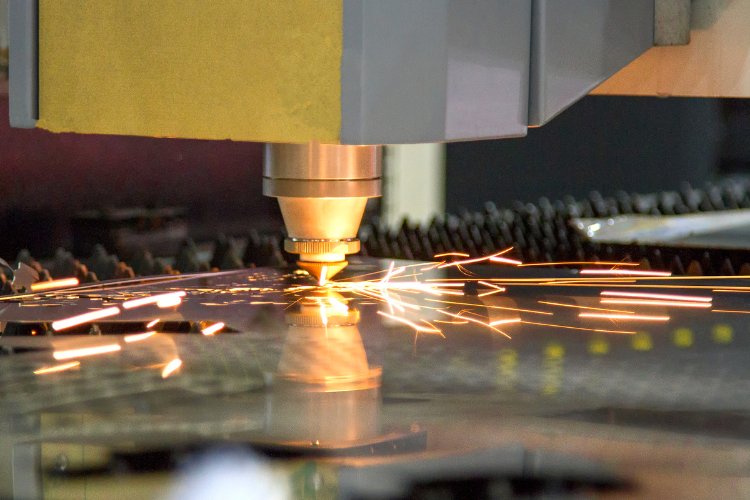

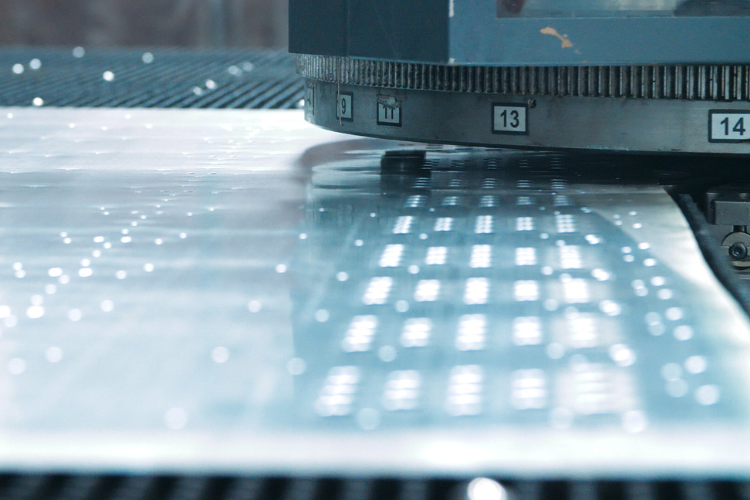

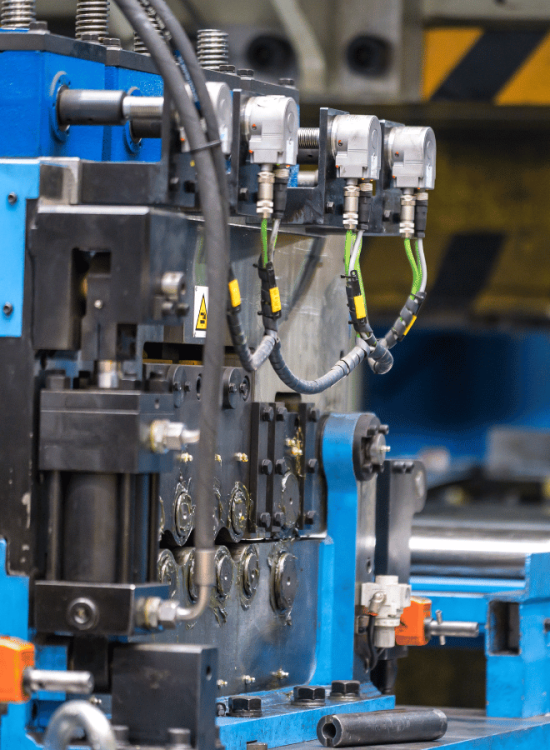

Inside Our Facility

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

Applicable Materials for Custom Metal Parts Fabrication

Carbon Steel

Carbon steel, distinguished by its carbon content, offers a balance of durability and malleability. It’s ideal for structural components and heavy-duty machinery due to its high strength. Its affordability and versatility make it a popular choice in various industrial applications, including custom metal fabrication. Moreover, its ability to be easily welded and fabricated enhances its suitability for diverse custom metal projects.

Nickel Alloys

Nickel alloys are known for their high corrosion resistance and ability to withstand extreme temperatures. They are often used in harsh environments, like chemical processing and power generation. These alloys are perfect for custom parts that demand longevity and resilience under challenging conditions. Their robustness and reliability make them a trusted choice for industry professionals seeking uncompromising quality.

Bronze

Bronze, an alloy of copper and tin, is valued for its toughness and corrosion resistance, making it ideal for decorative items, bearings, and restorations. Its market, as per LinkedIn, is projected to grow from USD 7755.6 million in 2022 to USD 8785.6 million by 2028, at a 2.1% CAGR, underscoring its rising demand and versatility.

Tool Steel

Tool steel is characterized by its hardness and ability to retain a cutting edge at high temperatures. It’s widely used for making custom tools and dies due to its abrasion resistance and durability. Zemetal takes pride in working with tool steel, ensuring that every custom tool we produce stands the test of time and performance. This material is essential in manufacturing industries where precision and longevity are paramount.

Carbon Steel

Nickel Alloys

Bronze

Tool Steel

Features of Custom Metal Parts Fabrication

Complex Geometry Capability

Custom metal fabrication excels in producing parts with complex shapes and intricate designs that standard processes cannot achieve. This feature is crucial for specialized applications where unique geometrical designs are necessary. Its ability to turn intricate design ideas into tangible realities is what sets it apart, making it a go-to solution for innovative projects.

High Durability

Custom fabricated parts are often more durable than mass-produced counterparts, as they are designed for specific applications and can be made from high-quality materials tailored for longevity. For example, a custom-fabricated gear made of high-grade steel for industrial machinery will typically last longer and perform better than a standard, off-the-shelf gear due to its bespoke design and material quality.

Benefits of Custom Metal Parts Fabrication

Optimized Supply Chain

By producing parts tailored to specific needs, companies can streamline their supply chain, reducing the risk of overproduction and excess inventory. Zemetal understands the importance of this efficiency. This not only optimizes production timelines but also minimizes waste, contributing to a more sustainable and cost-effective operation.

Stronger Brand Identity

Custom parts can enhance brand identity by allowing businesses to incorporate unique design elements that reflect their brand’s values and aesthetics. This customization extends beyond mere functionality, enabling companies to express their vision and ethos through the physical aspects of their products. This approach leads to a distinctive market presence, attracting customers who value unique and thoughtful design.

Applications of Custom Metal Parts Fabrication

Aerospace Industry

Custom metal parts are crucial in the aerospace industry for creating components that must meet strict weight, strength, and durability standards. These parts are used in everything from aircraft bodies to intricate engine components. The precision and quality assurance offered by custom fabrication are vital for the safety and efficiency of aerospace applications.

Medical Equipment Manufacturing

The medical industry relies on custom metal fabrication for creating surgical instruments, implants, and medical devices. For example, these parts require high precision and biocompatibility, often using specific alloys to ensure patient safety. Custom fabrication allows for the production of these complex and highly specialized items.

Automotive Industry

In automotive manufacturing, custom metal parts are used for engines, transmissions, and structural components. Custom fabrication allows for the design and production of parts that meet specific performance criteria and fit into the complex geometries of modern vehicles. Zemetal crafts precision automotive components for optimal performance and advanced technology integration.

Construction and Architecture

Custom metal fabrication plays a significant role in construction and architectural design, offering solutions for structural elements, decorative features, and bespoke fittings. These applications often require a combination of strength, aesthetics, and weather resistance, which custom fabrication can provide. The transformation of metal into architectural masterpieces reflects the fusion of art and engineering.

4 Things to Consider When Choosing Custom Metal Parts Fabrication

#1 Advanced CNC Machining Capabilities

Evaluate the fabricator’s ability to handle the complexity of the project, especially if it involves intricate designs or unique specifications. Their capability to work with diverse materials and employ advanced processes like CNC machining is crucial for precision and consistency. Zemetal specializes in meeting these complex demands with their state-of-the-art equipment and skilled craftsmanship.

#2 Batch Production Volume: 100-10,000 Units

When considering a fabricator, assess their capacity to handle specific batch sizes, ranging from small (100 units) to large-scale productions (up to 10,000 units). It’s crucial that they can manage order volume, whether it’s a limited run or mass production, without sacrificing the quality of the custom metal parts. This ensures that each needs, whether big or small, are met with the same level of dedication and expertise.

#3 Precision and Tolerances

Accuracy is vital in custom metal fabrication. Ensure the fabricator can achieve the precision and tolerances required for each parts, as even slight deviations can impact the product’s functionality. For example, in aerospace components where tolerances are often within thousandths of an inch, any minor inaccuracy can significantly affect the safety and performance of the aircraft.

#4 Cost Efficiency and Rapid Turnaround (e.g., 30-Day Completion for Bulk Orders)

Balance cost-effectiveness with quality. While custom fabrication can be more expensive, it’s essential to evaluate the overall value, considering factors like a 30-day completion time for bulk orders and the superior quality of the end product. This balance guarantees an investment in both efficiency and excellence rather than a mere payment for a service.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.