Metal Finishing Services

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

Explore Our Premium Metal Fabrication Range

Taking pride in our advanced metal fabrication services, Zemetal sets the industry standard with exceptional quality and precision. Our expertise extends to a diverse range of metal surface treatments, ensuring that every project meets the highest standards of durability and aesthetics.

We understand the intricate needs of your projects, striving to exceed expectations in every detail. Our state-of-the-art facilities are equipped to handle a variety of metal finishing services, employing cutting-edge techniques that define the future of metal fabrication.

Trust us to deliver unparalleled craftsmanship and innovative solutions for all your metal fabrication needs.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

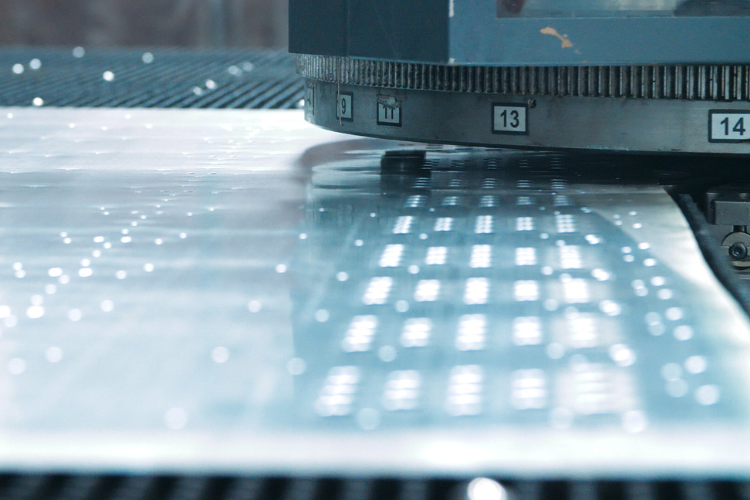

Inside Our Facility

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

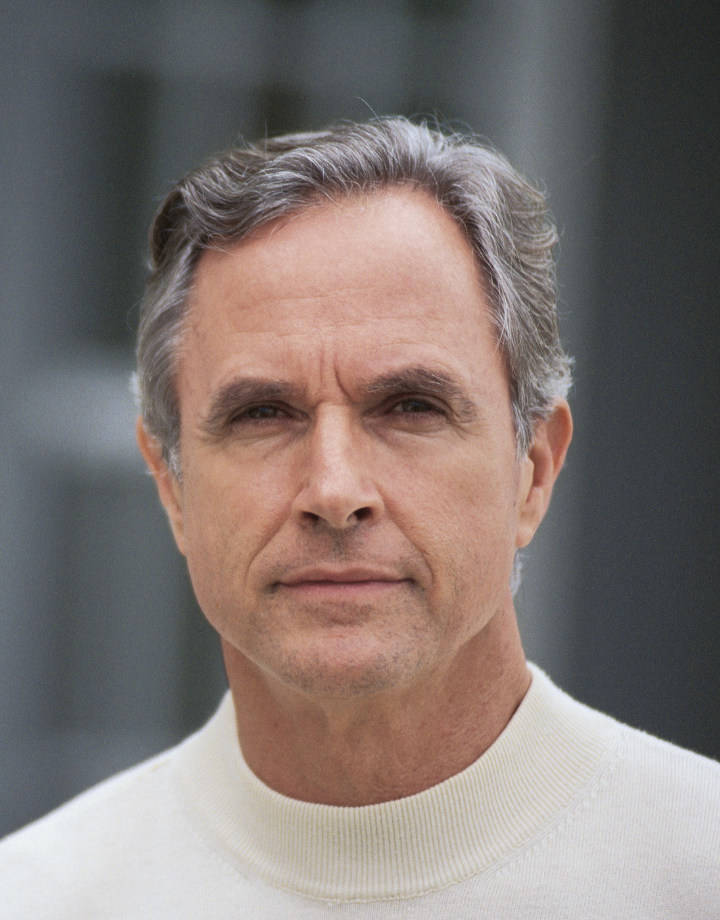

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

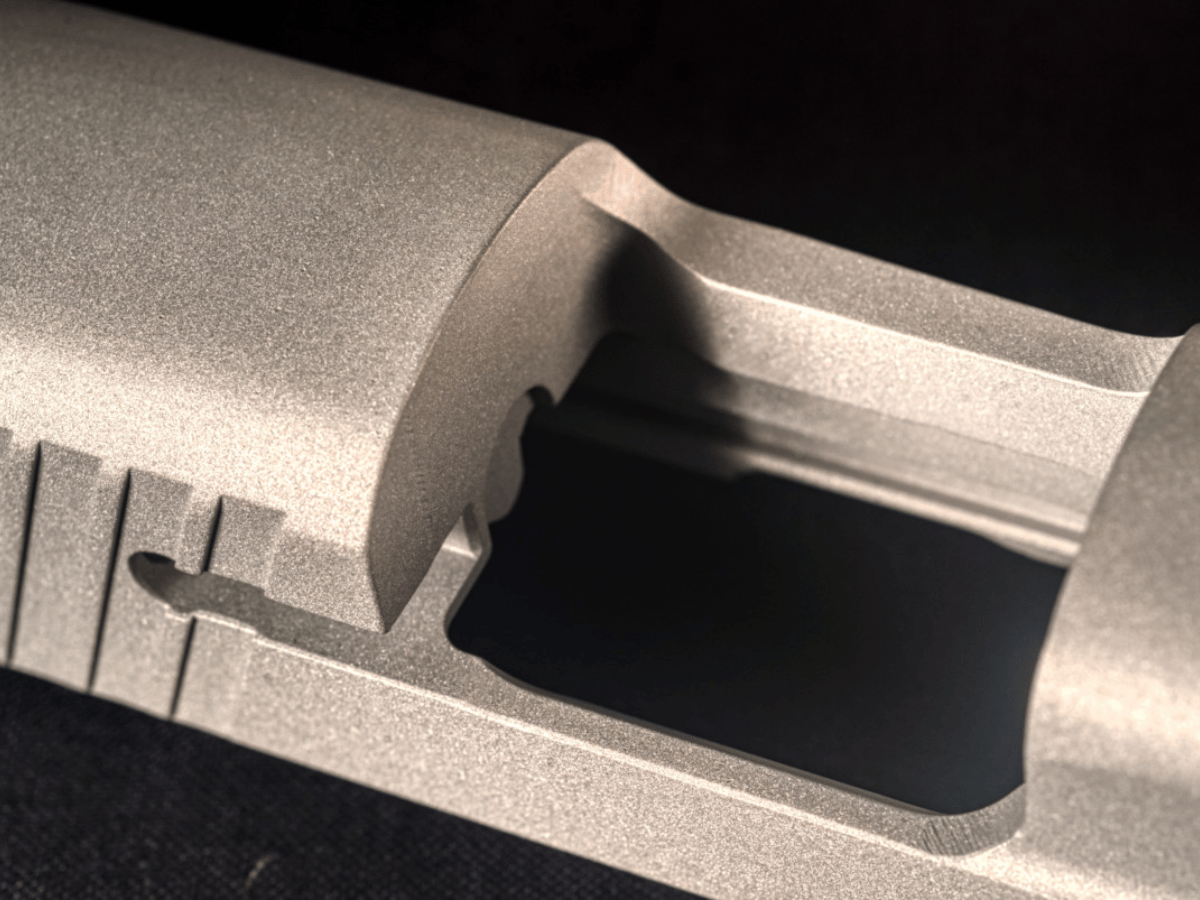

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

Types of Metal Finishing Services

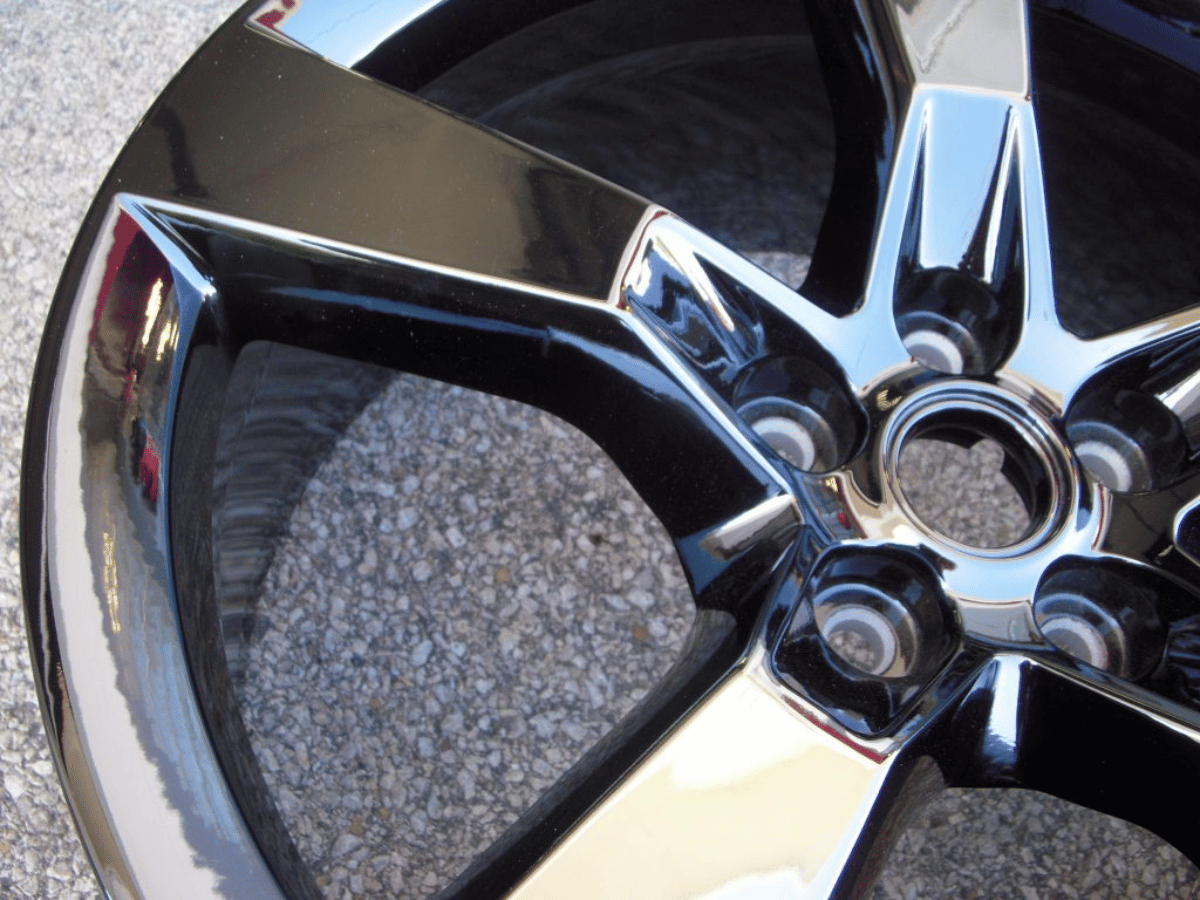

PVD Chrome Plating

PVD (Physical Vapor Deposition) Chrome Plating is a cutting-edge technique that provides a decorative and durable chrome finish. This process involves vaporizing metals in a vacuum environment, resulting in a thin, yet highly adherent layer. Ideal for automotive and architectural applications, PVD chrome plating offers superior corrosion resistance and a sleek, mirror-like appearance.

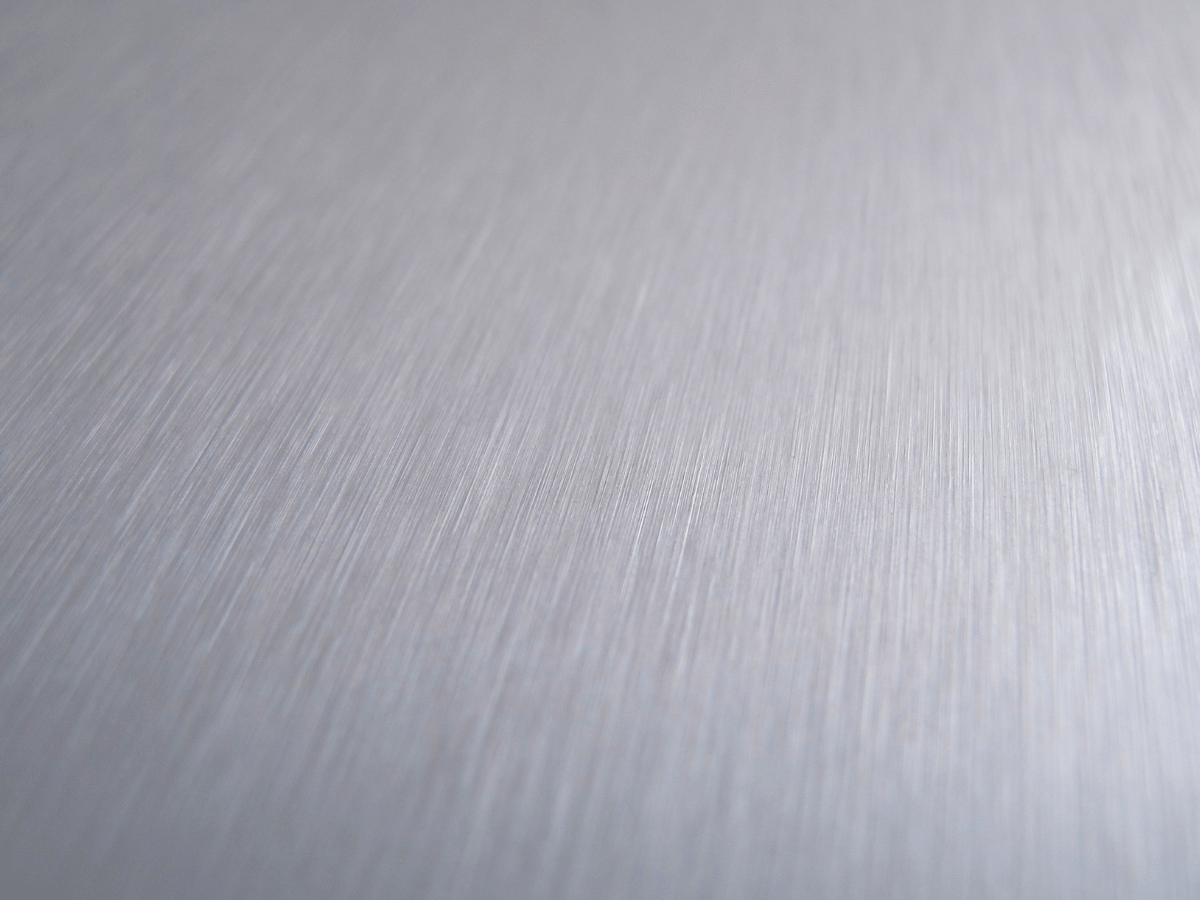

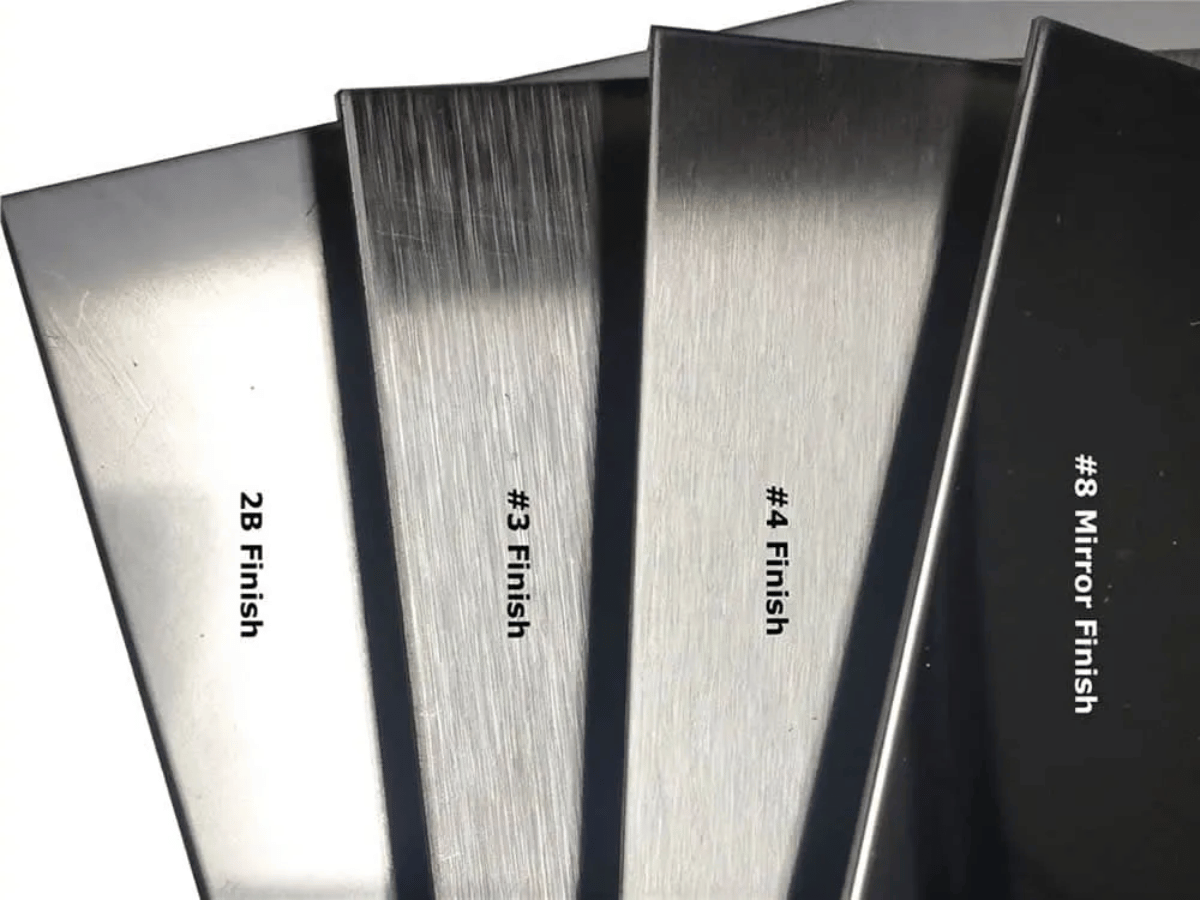

Stainless Steel Finish

Stainless steel finishes are widely valued for their aesthetic appeal and corrosion resistance. Techniques range from brushing and polishing to more intricate patterns, enhancing both the appearance and durability of the metal. These finishes are essential in industries where both hygiene and visual appeal are crucial, such as in kitchen appliances and medical equipment.

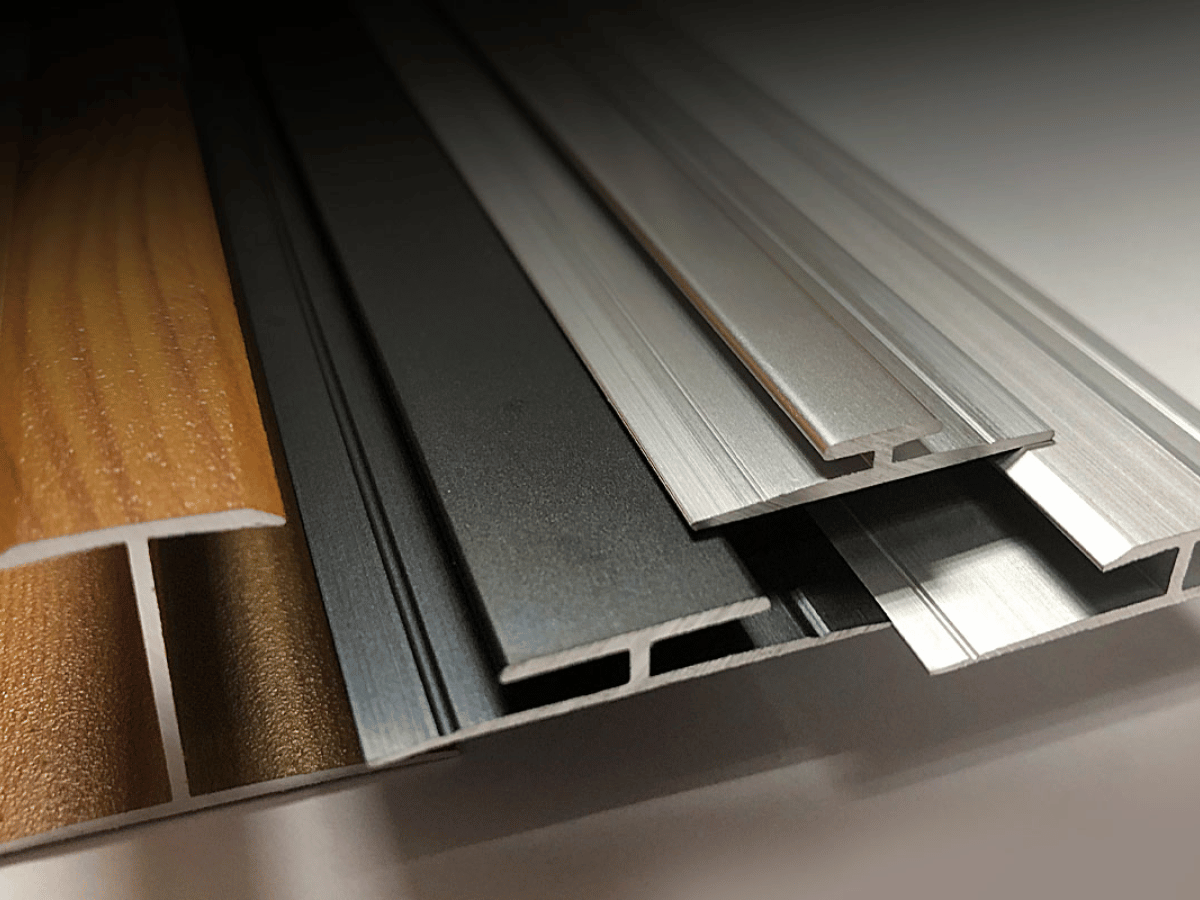

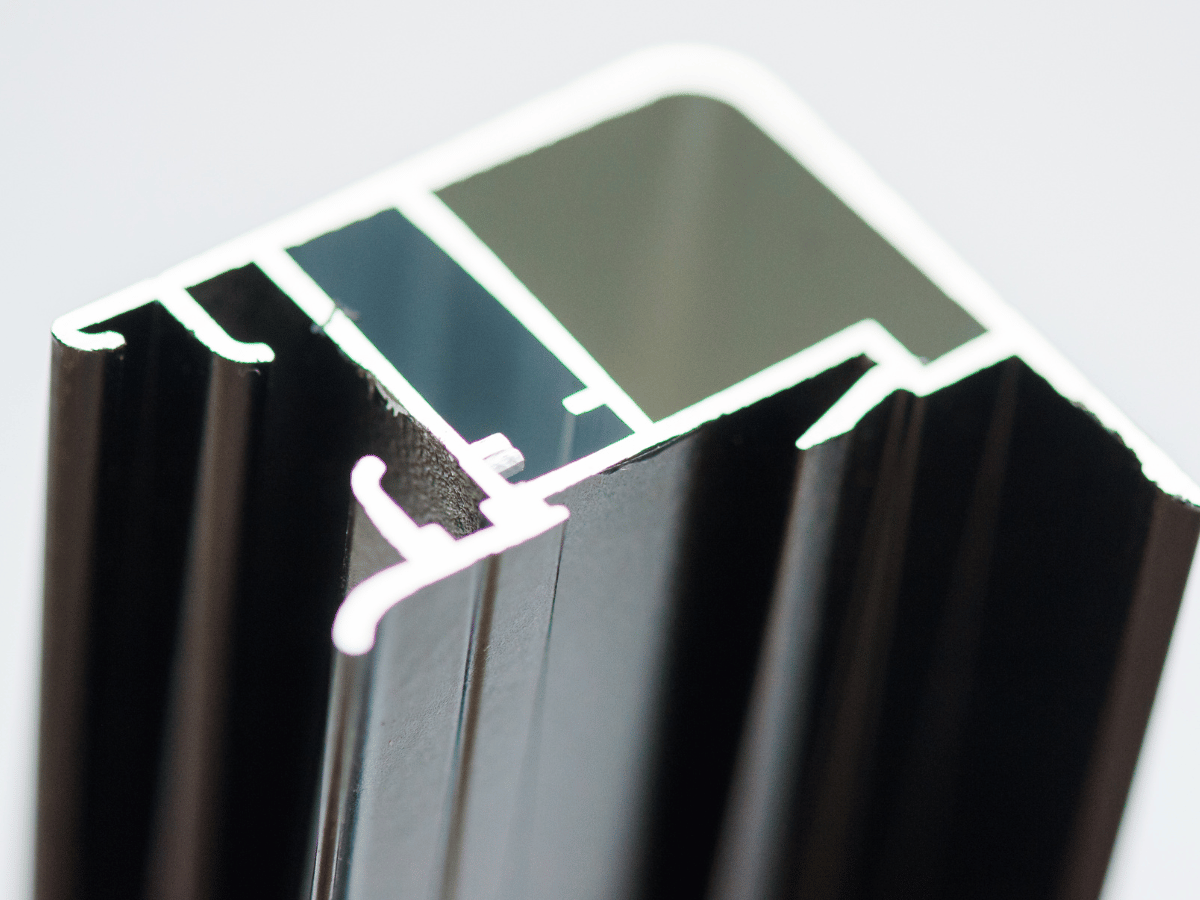

Anodized Aluminum Finish

Anodized aluminum finishing involves an electrochemical process that converts the metal surface into a decorative, durable and anodic oxide finish. This method is particularly suitable for outdoor applications due to its UV resistance and the ability to withstand harsh weather conditions. Zemetal’s finishing technique in their metal fabrication servicing, ensures that aluminum components offer long lasting resilience in outdoor settings.

Aluminum Surface Treatments

Aluminum surface treatments encompass a range of processes designed to improve the metal’s appearance and longevity. Methods like anodizing, painting, and powder coating enhance aesthetic appeal and protect against environmental factors. These treatments are essential for products exposed to the elements or those requiring a specific visual impact.

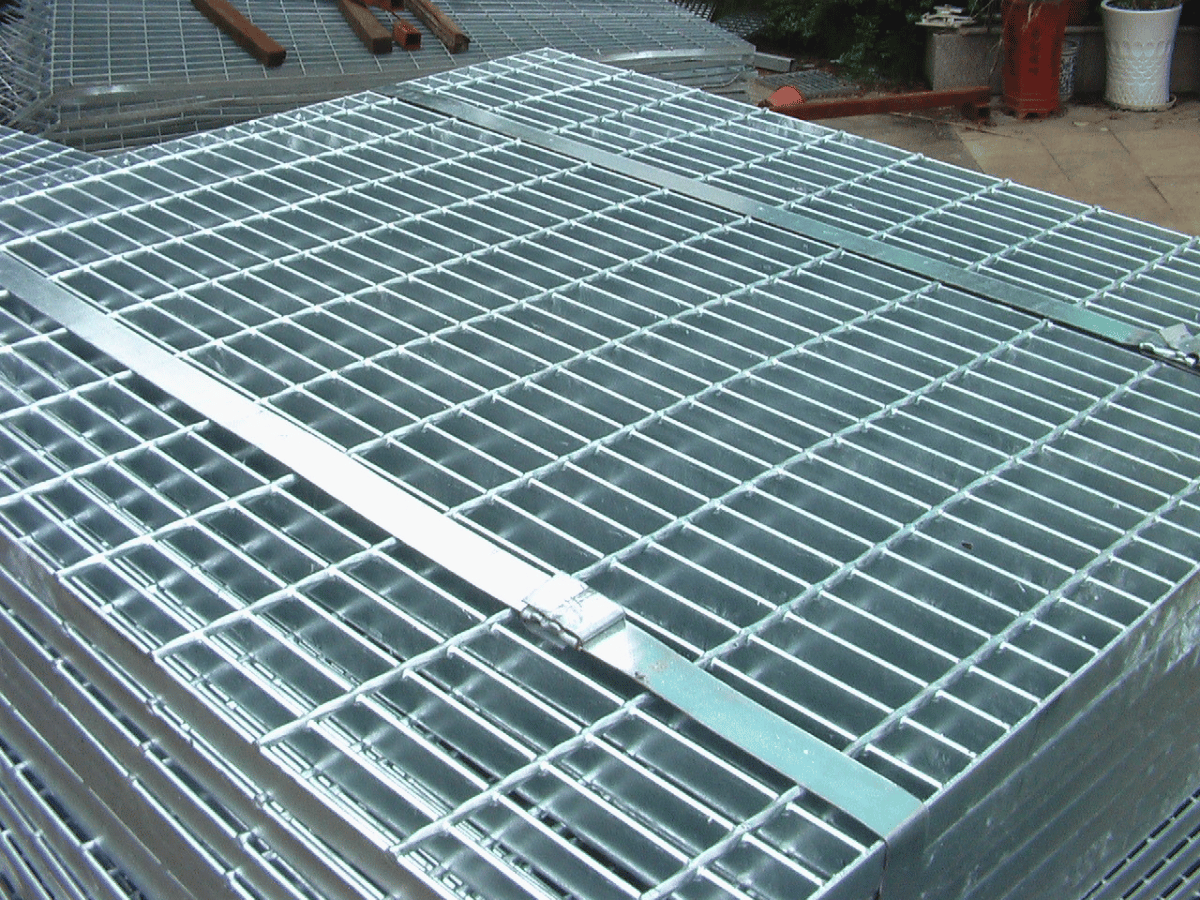

Surface Treatments for Steel

Surface treatments for steel include processes like bluing, phosphating, and galvanizing. These methods enhance steel’s resistance to rust and corrosion, making it suitable for a wide range of applications, from construction to automotive parts. Custom metal finishing options are available to meet specific industry requirements.

Stainless Steel Polished Finish

The stainless steel polished finish is highly sought after for its mirror-like shine and sleek appearance. Achieved through grinding and buffing, this finish is not only aesthetically pleasing but also enhances the material’s resistance to tarnishing and corrosion, making it ideal for decorative and architectural uses.

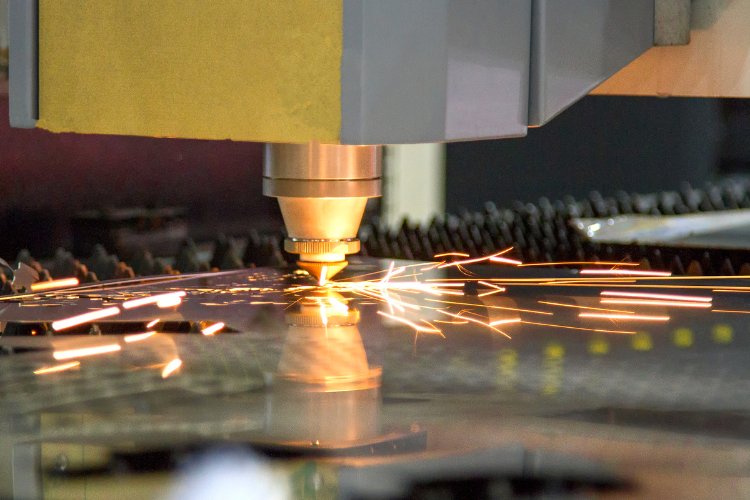

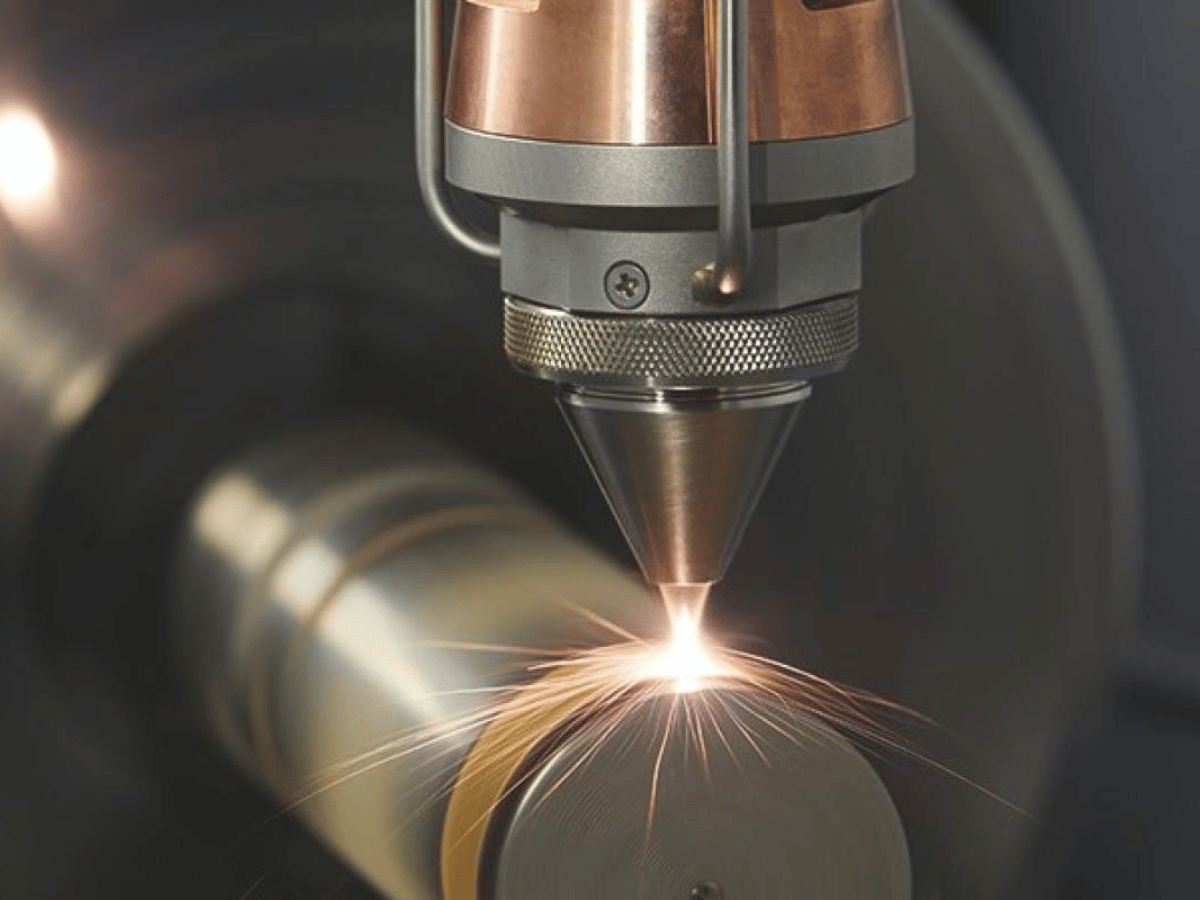

Laser Surface Treatment

Laser surface treatment involves using concentrated laser beams to modify the surface properties of metals. This advanced method can improve hardness, wear resistance, and even create intricate patterns on metal surfaces. It’s widely used in precision engineering and manufacturing sectors for its accuracy and efficiency.

Hot Dip Galvanized Finish

Hot dip galvanizing is a process of coating steel or iron with a layer of zinc, providing excellent protection against corrosion. This finish is essential for structural steel and outdoor metal products, offering long-lasting durability in even the most challenging environments.

Anodized Surface

An anodized surface on metals, especially aluminum, provides a hard, protective layer while also allowing for vibrant coloration. This electrochemical process enhances wear and corrosion resistance, making it suitable for various applications, from consumer electronics to architectural elements.

Chromate Finish

Chromate finishes are used to coat metals like aluminum, steel, and zinc for increased corrosion resistance. The process involves applying a chromate conversion coating, which also serves as a decorative finish and a primer for additional coatings. This finish is vital for components exposed to harsh environments.

Applicable Materials for Metal Finishing Services

Aluminum

Aluminum is a versatile material widely used in metal finishing services due to its resistance to corrosion. Finishing techniques like anodizing, powder coating, and painting not only enhance its appearance but also significantly improve its durability and longevity. Aluminum is ideal for applications ranging from automotive parts to architectural elements, benefiting from these treatments in both function and form.

Stainless Steel

Stainless steel is known for its strength and resistance to corrosion, making it a prime candidate for various metal finishing processes. Polishing and passivation are common methods that enhance its natural luster and increase its resistance to tarnishing and rust. This material is extensively used in industries where both aesthetics and hygiene are paramount, such as in kitchenware, medical instruments, and construction.

Steel

Steel, known for its robustness and versatility, is widely used in metal fabrication and benefits greatly from finishing services. Processes like galvanizing, bluing, and powder coating not only protect steel from corrosion but also improve its appearance. These treatments are essential for steel used in construction, automotive, and machinery industries, where durability and longevity are critical.

Copper and Brass

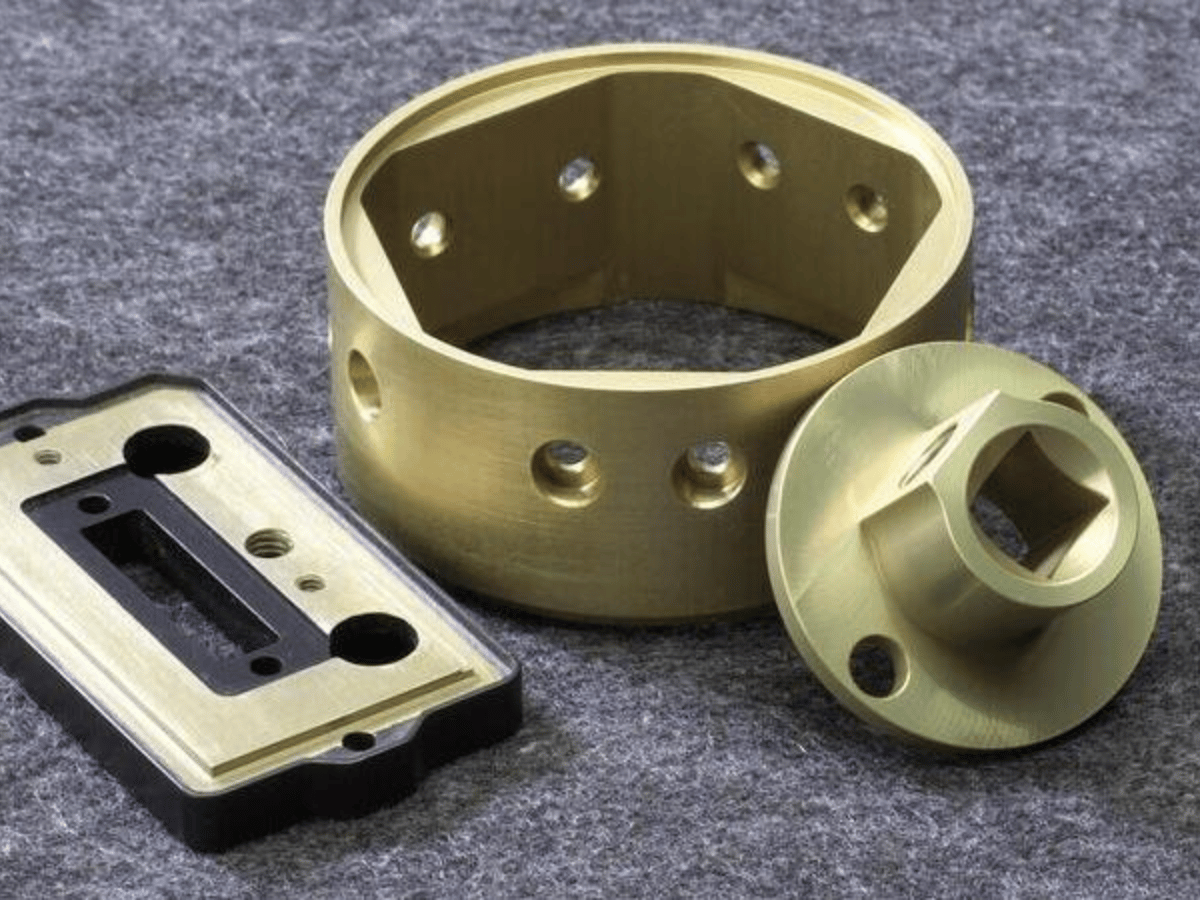

Copper and brass are popular for their unique color and sheen, commonly used in decorative and architectural applications. Finishing processes like lacquering, patinating, and polishing are employed to enhance their natural beauty and prevent tarnishing. These metals are used in Zemetal’s fabrication services for interior design, plumbing fixtures, and ornamental work, where their aesthetic qualities are highly valued.

Aluminum

Stainless Steel

Steel

Copper and Brass

Features of Metal Finishing Services

Durability Enhancement

Metal finishing services significantly enhance the durability of metals by adding protective layers that resist wear, corrosion, and environmental impact. This process extends the life of metal products, making them more robust for industrial and commercial applications.

Aesthetic Improvement

These services offer a wide range of aesthetic improvements, including polishing, coloring, and texturing. This versatility allows for customization in design, making metal products visually appealing for decorative and architectural uses.

Surface Property Modification

Zemetal’s metal finishing services can alter surface properties like electrical conductivity, friction, and chemical resistance. This customization is crucial for specialized industrial applications, ensuring that metal products meet specific functional requirements.

Benefits of Metal Finishing Services

Increased Product Lifespan

By providing additional protection against environmental factors and wear, metal finishing services greatly increase the lifespan of metal products. This long-term durability is a key benefit, reducing the need for frequent replacements and maintenance.

Enhanced Product Value

The improved aesthetics and functionality of metal products through finishing services add significant value. This enhancement boosts the market appeal and usability of the products, making them more desirable to consumers and industries.

Versatility in Applications

The wide range of finishing techniques available allows for a broad spectrum of applications across various industries. From automotive parts to architectural designs, the versatility of metal finishing services makes them indispensable in numerous sectors.

Applications of Metal Finishing Services

Automotive Industry

In the automotive industry, metal finishing services are crucial for both aesthetic and functional purposes. Techniques like chrome plating and anodizing are used to enhance the durability and appearance of vehicle components. These finishes are applied to parts such as wheels, trim, and engine components, ensuring longevity and visual appeal.

Aerospace Industry

The aerospace industry relies heavily on metal finishing for corrosion resistance and strength enhancement. Processes like passivation and anodizing are used to protect aircraft parts against harsh environmental conditions. These treatments ensure the safety, efficiency, and longevity of aerospace components. Zemetal’s expertise in these treatments contributes significantly to the safety and longevity of aerospace components.

Consumer Electronics

Metal finishing is integral in the consumer electronics sector, where it is used to improve product aesthetics and durability. Techniques like electroplating and powder coating are applied to devices such as smartphones, laptops, and cameras, providing a sleek appearance and resistance to wear.

Architectural and Construction Industry

In architecture and construction, metal finishing services are used to enhance both the durability and aesthetic appeal of structures. For example, stainless steel polishing and anodizing of aluminum are commonly used in building facades, railings, and fixtures, offering both a visually striking appearance and resistance to environmental factors.

Automotive Industry

Aerospace Industry

Consumer Electronics

Architectural and Construction Industry

4 Things to Consider When Choosing Metal Finishing Services

#1 Material Compatibility

When selecting metal finishing services, it’s crucial to consider the compatibility of the finishing process with the base material. Different metals react uniquely to various finishing techniques. For instance, aluminum requires specific treatments like anodizing for optimal results, while stainless steel might benefit more from electropolishing. Material-specific requirements ensure effectiveness and the longevity of the final product.

#2 Desired Finish and Aesthetics

The desired appearance and finish of the final product are key factors in choosing a metal finishing service. Each finishing technique, from powder coating to chrome plating, imparts a distinct look and feel. For example, a manufacturer aiming for a high-gloss, decorative finish might opt for PVD chrome plating, while a matte, durable finish could be achieved through powder coating.

#3 Environmental Conditions

Consideration of the environmental conditions in which the finished product will be used is paramount. Exposure to elements like moisture, chemicals, or UV radiation can significantly impact the choice of finishing. Selecting a finish that can withstand specific environmental stressors is key to maintaining the integrity and longevity of the product.

#4 Compliance and Standards

Compliance with industry standards and regulations is another critical factor in selecting metal finishing services. Certain industries, such as aerospace or medical, have stringent requirements regarding surface treatments to ensure safety and performance. Zemetal’s metal finishing service adheres to relevant standards and can provide certifications if necessary.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.