Galvanizing Service

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

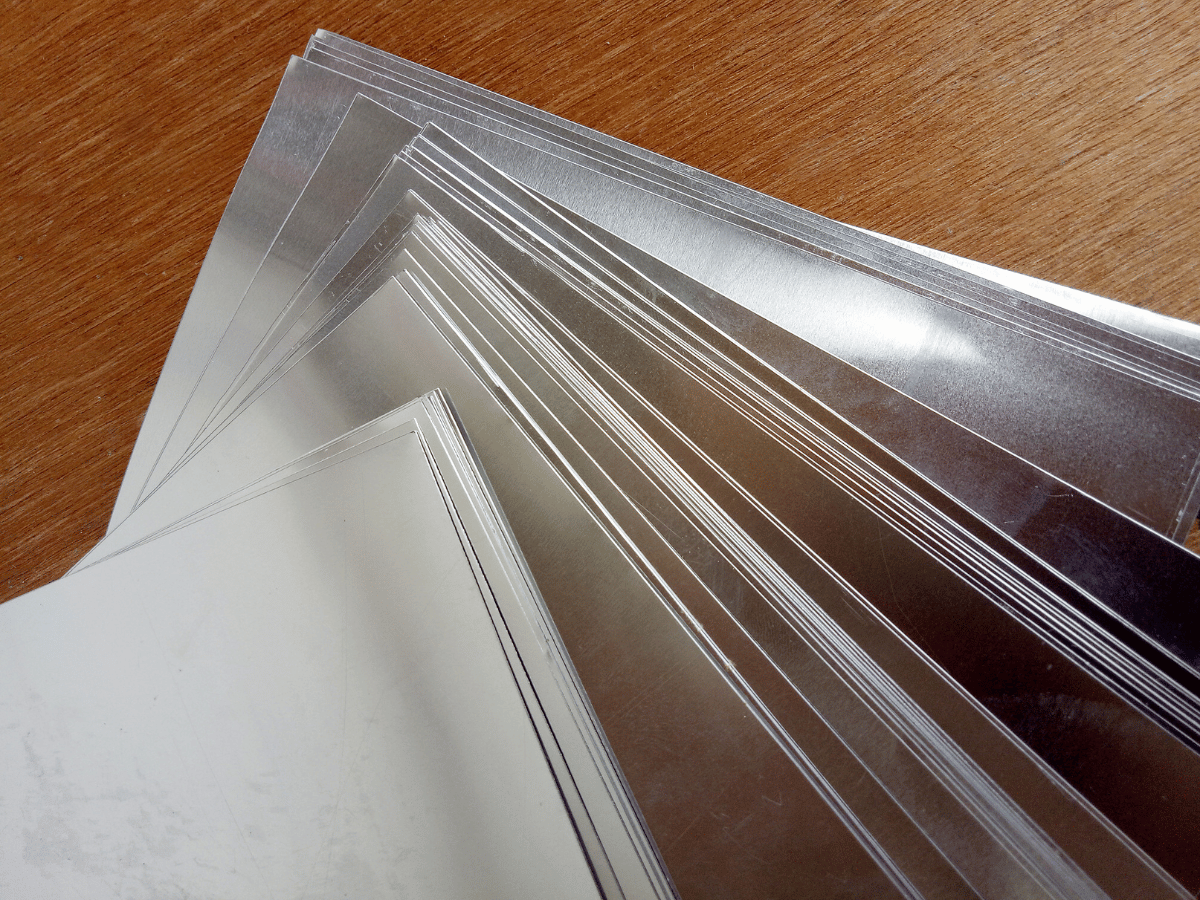

Explore Our Premium Metal Fabrication Range

At Zemetal, we understand the critical role that metal fabrication plays in the industrial and commercial sectors. Our commitment to providing top-tier galvanizing services stems from a deep understanding of the challenges and requirements faced by businesses in these fields.

Our approach to galvanizing is rooted in a blend of traditional craftsmanship and modern technology. Our team is dedicated to providing solutions that are not only effective but also cost-efficient, ensuring that your investment in galvanizing services yields long-term benefits for your business.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

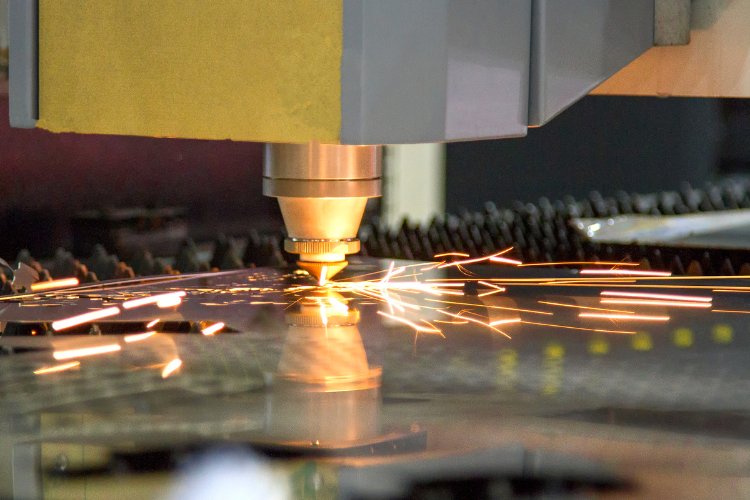

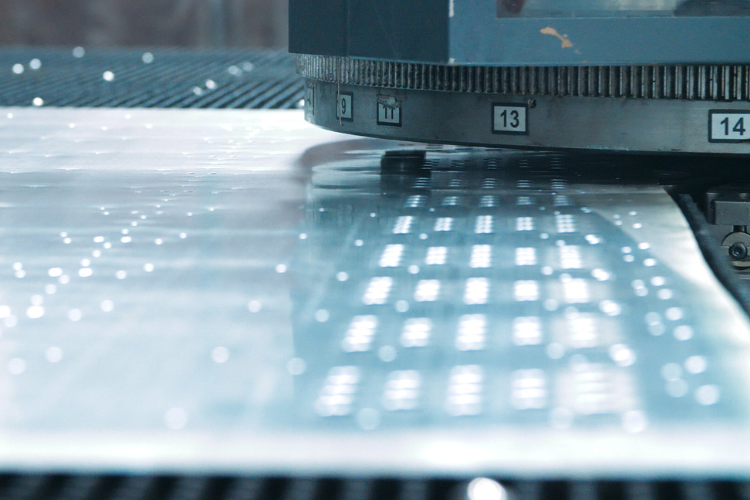

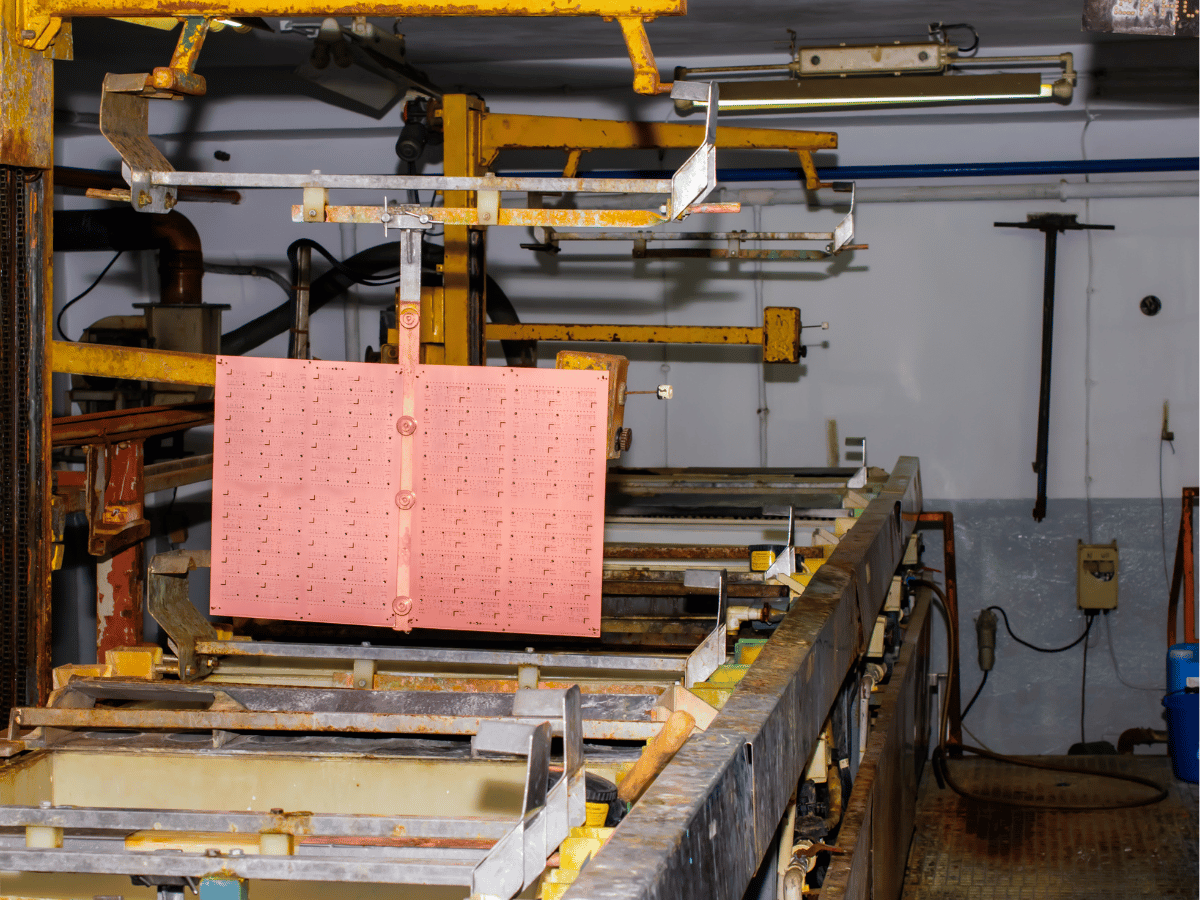

Inside Our Facility

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

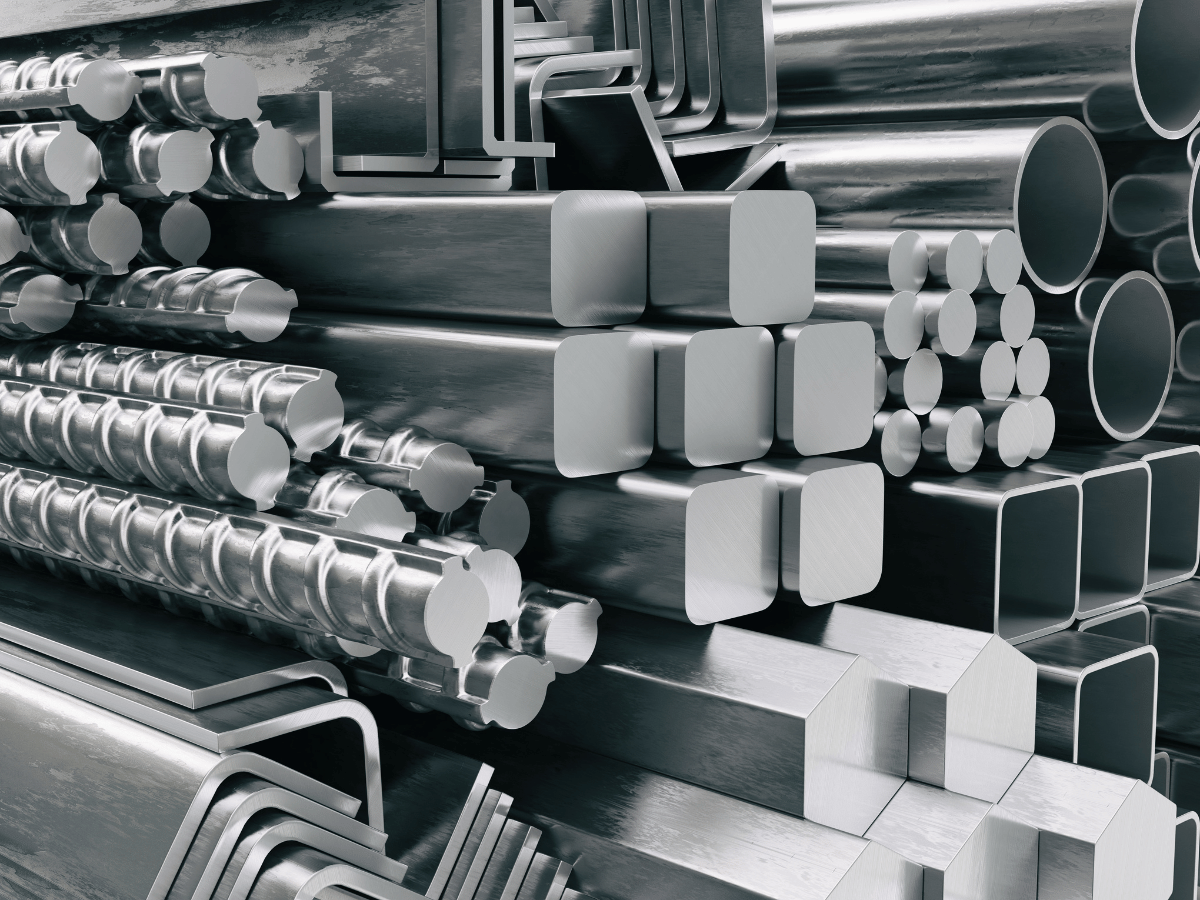

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

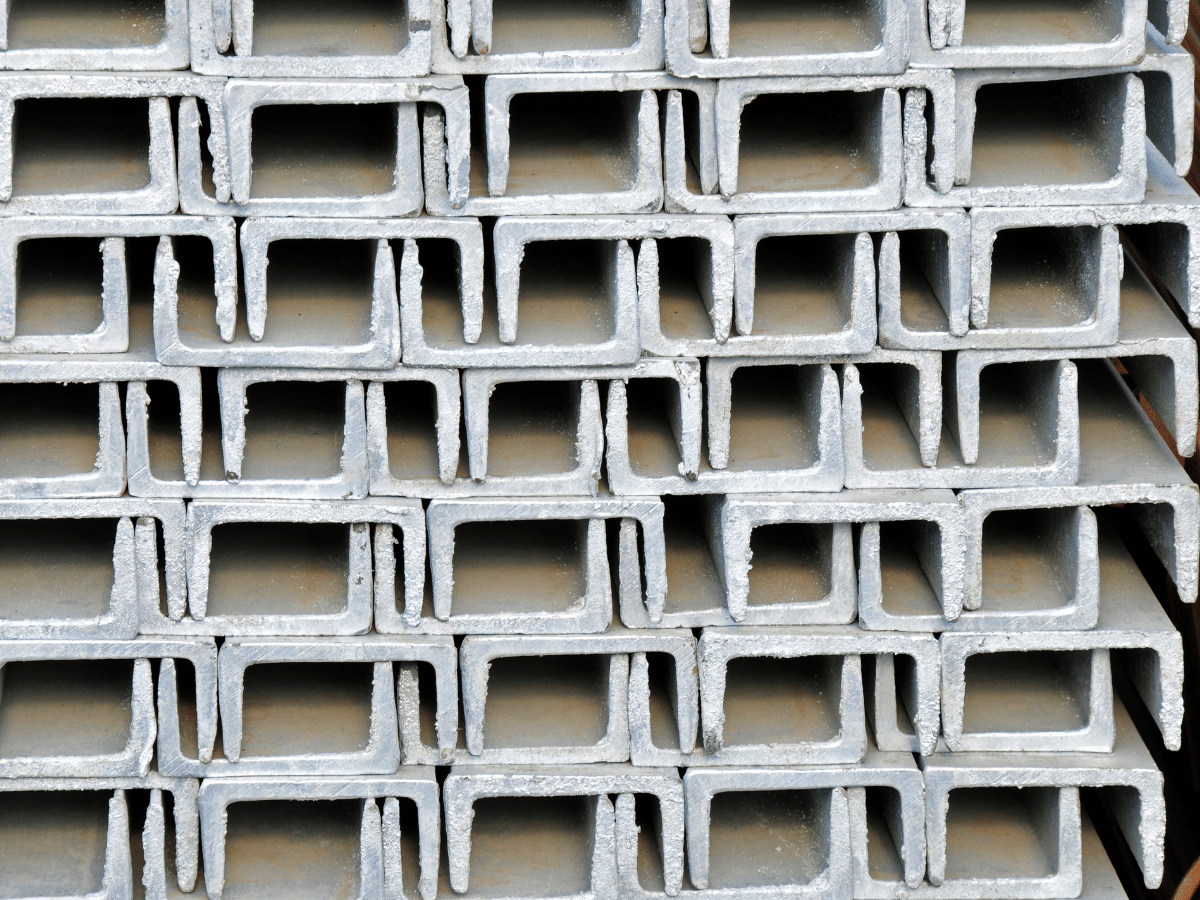

Types of Galvanizing Services

Hot Dip Galvanizing

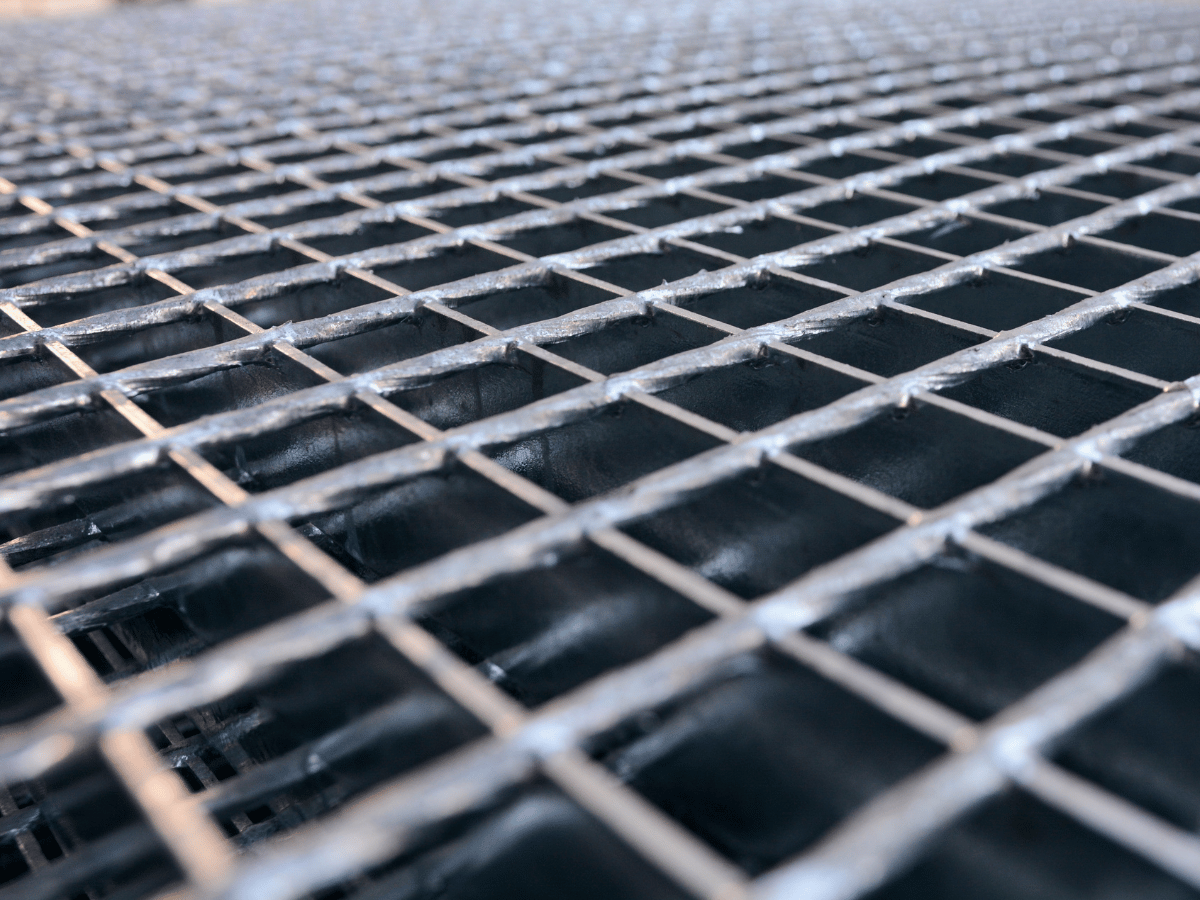

Hot dip galvanizing is a process where metal components are immersed in a bath of molten zinc. At Zemetal, this technique forms a thick, protective zinc coating that is highly resistant to corrosion. Ideal for structural steel and outdoor applications, hot dip galvanizing creates a durable and long-lasting barrier, effectively protecting the metal from harsh environmental conditions.

Zinc Electroplating

Zinc electroplating involves the application of a zinc coating to a metal surface using an electrical current. This method offers a thinner coating compared to hot dip galvanizing and is typically used for smaller, precision components. The process can be customized with various post-treatment options, like chromate conversion coatings, to enhance the appearance and durability of the finish.

Welding Galvanized Steel MIG

Welding galvanized steel with Metal Inert Gas requires careful technique to maintain the integrity of the zinc coating while achieving strong welds. This method is particularly challenging due to the high melting point of steel compared to zinc. Appropriate ventilation and temperature control are crucial to prevent the zinc from vaporizing and to ensure the weld area is free from zinc contamination, which can lead to weld porosity.

Cold Dip Galvanizing

Cold dip galvanizing, or cold galvanizing, involves applying a zinc-rich paint or coating to the metal surface. This method is often used for spot repairs on previously galvanized steel or in situations where hot dip galvanizing is impractical. While not as durable as hot dip galvanizing, cold galvanizing is flexible and can be applied on-site, offering a convenient solution for maintenance and repair work.

Bright Zinc Plating

Bright zinc plating is a variation of zinc electroplating that results in a glossy, decorative finish. This process is particularly popular in the automotive and consumer goods industries, where the visual aspect of metal components is important. In addition to its aesthetic appeal, bright zinc plating provides a moderate level of corrosion protection and can be further enhanced with various sealants or passivation treatments.

Trivalent Zinc Plating

Trivalent zinc plating is an eco-friendlier alternative to traditional zinc plating methods. It utilizes trivalent chromium in place of hexavalent chromium, reducing environmental and health hazards. This method offers effective corrosion resistance and is becoming increasingly popular in industries where environmental regulations are stringent.

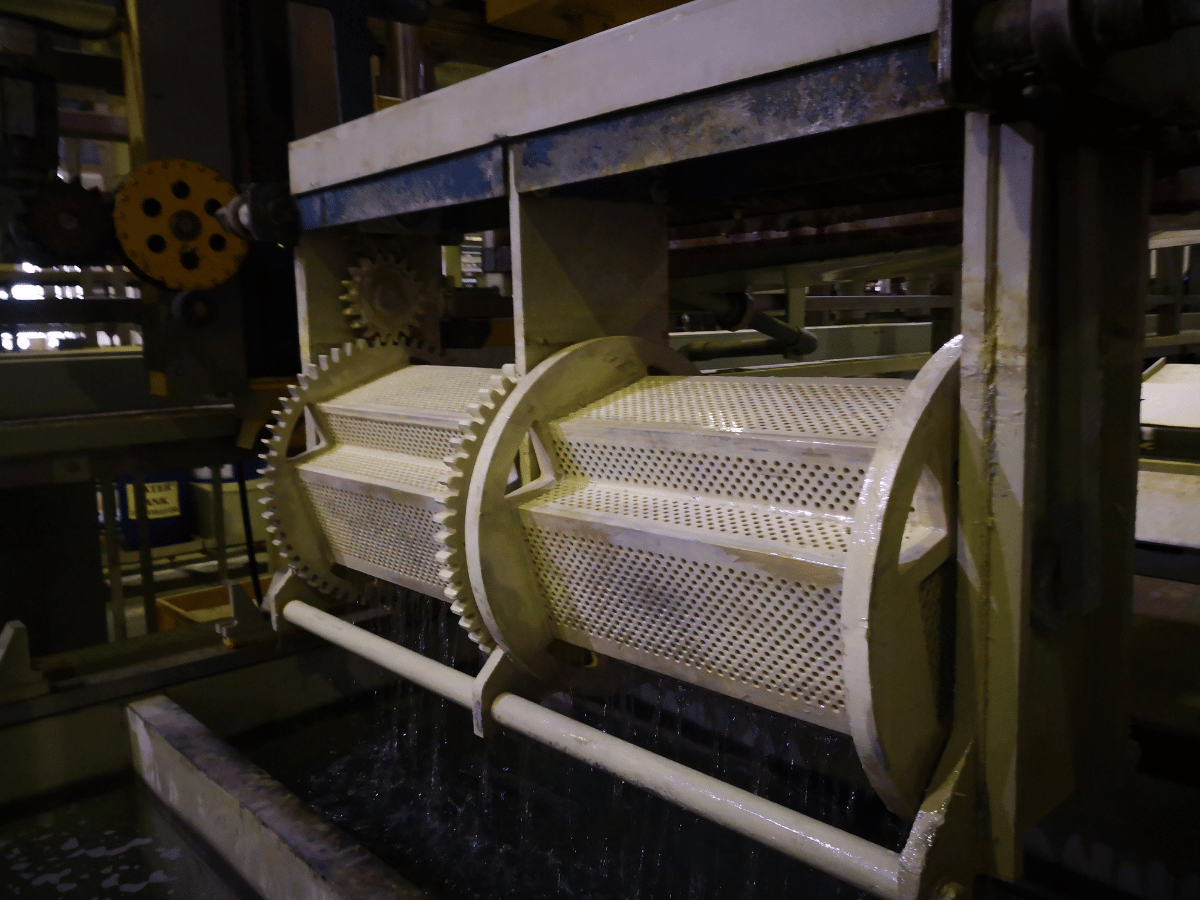

Barrel Zinc Plating

Barrel zinc plating is an efficient method for galvanizing large quantities of small parts. In this process, parts are placed in a rotating barrel, which tumbles them in a zinc solution, ensuring even coverage and a consistent finish. This method is cost-effective and ideal for fasteners, nails, and small components, where individual treatment would be impractical and expensive.

Alkaline Zinc Plating

Alkaline zinc plating is distinguished by its use of an alkaline electrolyte solution, as opposed to the acidic solutions used in other plating processes. This method is particularly effective for coating complex geometries and internal surfaces, providing a smooth and uniform finish. Alkaline zinc plating is ideal for intricate parts where coverage in hard-to-reach areas is crucial for overall performance and longevity.

Zinc Plating Anode

In the zinc plating anode process, a zinc anode is used in the electroplating bath. The anode plays a crucial role, as it gradually dissolves in the electrolyte solution and deposits zinc onto the cathodic metal part. This method ensures a consistent and high-quality zinc coating. The choice of anode material and its maintenance are critical factors in achieving the desired plating quality and efficiency.

Applicable Materials for Galvanizing Services

Steel and Iron

Steel and iron are the most commonly galvanized materials. Their inherent strength and durability make them ideal for a wide range of applications, from construction to automotive parts. Galvanizing enhances their resistance to rust and corrosion, significantly extending their lifespan. The resulting zinc coating bonds with steel or iron, forming a series of zinc-iron alloy layers topped with a pure zinc outer layer.

Alloy Steels

Alloy steels, which are steels mixed with other elements to improve certain characteristics like strength or resistance to wear, can also be galvanized. However, the galvanizing process for alloy steels requires careful consideration of the alloying elements. Zemetal recognizes that some alloys may need specific pre-treatment or altered galvanizing procedures to ensure proper adhesion and coating quality.

Cast Iron

Galvanizing cast iron, including ductile and malleable iron, is less common but still practiced for specific applications. Cast iron presents unique challenges for galvanizing due to its high carbon content, which can lead to the formation of graphite on the surface during the process. To mitigate this, special pre-treatment processes, such as abrasive blasting, are employed to prepare the cast iron surface for galvanizing.

Steel and Iron

Alloy Steels

Cast Iron

Features and Benefits of Galvanizing Services

Features of Galvanizing Services

Corrosion Resistance

One of the most significant benefits of galvanizing is its superior corrosion resistance. The zinc coating acts as a physical barrier, protecting the underlying metal from environmental factors like moisture and pollutants. This barrier significantly reduces the rate of corrosion, effectively prolonging the lifespan of the metal components.

Self-Healing Properties

A unique feature of the zinc coating is its self-healing properties. For instance, if the galvanized surface is scratched or damaged, exposing the base metal, the surrounding zinc reacts with the environment to form a protective layer of zinc carbonate over the exposed area. This process helps prevent rust in the damaged spot, maintaining the integrity of the overall protective layer.

Benefits of Galvanizing Services

Reduced Maintenance and Replacement Costs

At Zemetal, the galvanizing services significantly reduce maintenance and replacement costs over the lifetime of a product. The durable nature of the zinc coating means that galvanized metal requires less frequent repairs and replacements, translating into substantial cost savings, especially in large-scale or infrastructural applications.

Eco-Friendly Lifecycle

According to Monnig Industries, galvanized steel boasts an eco-friendly lifecycle. The extended durability of galvanized products means less frequent manufacturing and lower resource consumption. Moreover, both steel and zinc are fully recyclable, minimizing environmental impact and aligning with sustainable resource management practices.

Applications for Galvanizing Services

Construction and Infrastructure

The construction and infrastructure sector heavily relies on galvanizing services to enhance the durability and longevity of metal components. At Zemetal, steel is commonly used in the fabrication of structural elements. The ability of galvanized materials to withstand harsh outdoor conditions without significant deterioration makes it an essential choice for long-lasting, maintenance-free structures.

Automotive and Transportation

Components like body panels, frames, and chassis parts in vehicles are frequently galvanized to ward off rust and corrosion. Galvanizing plays a key role in safeguarding numerous structural and operational parts against corrosive elements. Reflecting the significance of this process, the galvanizing market is projected to expand at a compound annual growth rate (CAGR) of 4.9% from 2022 to 2027, as reported by Industry ARC.

Energy and Utilities

Galvanizing services are critical for protecting infrastructure against environmental factors. This includes components used in power plants, electrical grids, and renewable energy installations like wind turbines and solar panel frames. The durability and low maintenance requirements of galvanized components are especially beneficial in hard-to-access locations, making it a preferred choice in the energy and utilities industry.

3 Things to Consider When Choosing Galvanizing Services

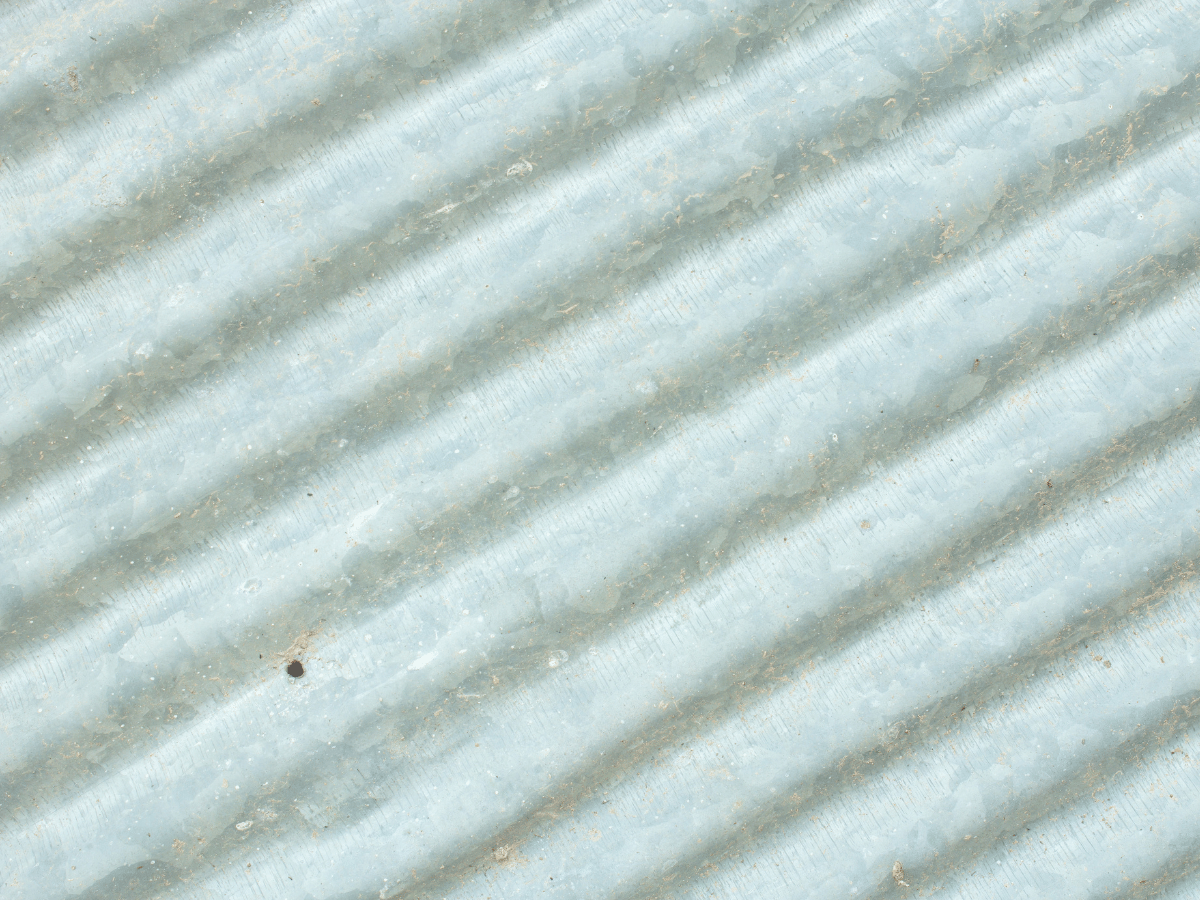

#1 Zinc Coating Thickness

The thickness is a key determinant of the level of corrosion resistance and the durability of the galvanized product. Different environments and applications demand varying thicknesses for optimal protection. For example, metals used in harsher environments, like coastal areas or industrial settings with high exposure to corrosive elements, may require thicker zinc coatings compared to those used in milder conditions.

#2 Galvanizing Process Compatibility

Different galvanizing processes offer unique characteristics and are suitable for various types of metal products. At Zemetal, factors such as the size, shape, and type of metal being galvanized influences the choice of the galvanizing process. It’s important to evaluate the compatibility of the available galvanizing services with your specific metal components to ensure that the process chosen will effectively meet the desired quality.

#3 Post-Galvanizing Finishing and Aesthetics

The aesthetic outcome and finishing options available with galvanizing services are also important considerations. Some applications may require a specific visual appearance. Assessing your requirements in terms of the final appearance and additional protective properties will help in selecting a galvanizing service that aligns with both functional and aesthetic needs.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.