Powder Coated Steel

Explore Our Premium Metal Fabrication Range

Zemetal: Who We Are

Our Founding Journey

Inside Our Facility

Innovation & Development

Certification Excellence

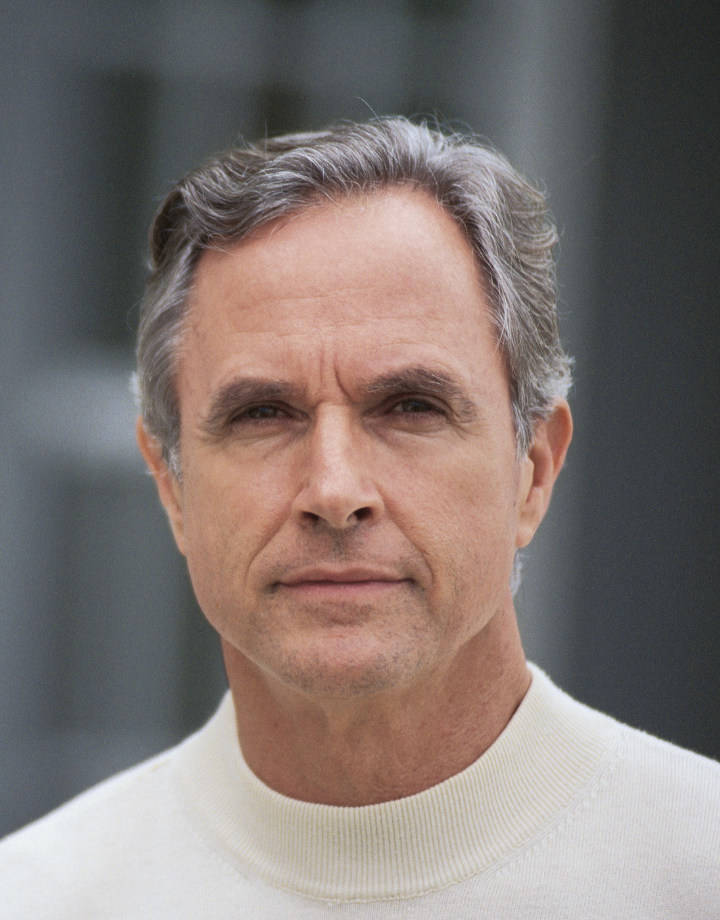

Meet the Experts Behind Zemetal

01

Media Team

02

Quality Assurance Team

03

Research & Development Team

04

Engineering & Design Team

Empowering Goals With Us

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

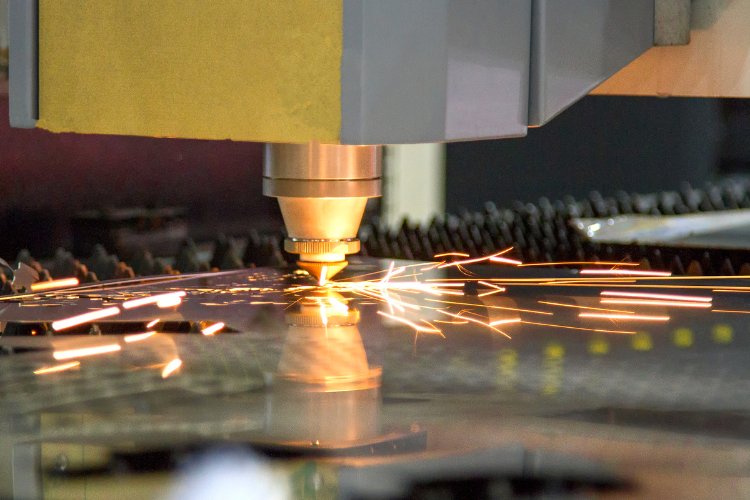

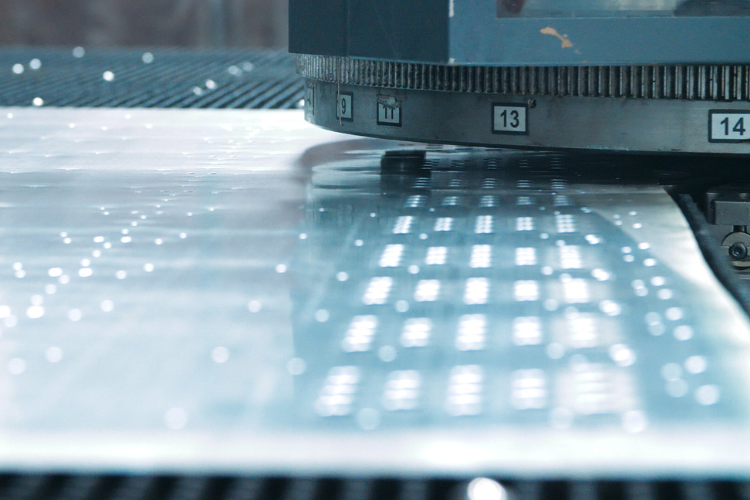

Advanced Technology & Equipment

Expert Team & Quality Assurance

Flexible Production Capacity

Timely Delivery & Customer Support

Sustainable Practices & Material Options

Applicable Materials for Powder Coated Steel

Aluminum Plate

Aluminum stands out for its lightweight properties and flexibility, making it a popular choice for powder coated steel applications. Its ability to be easily customized allows for a wide range of designs and shapes, ideal for various industrial uses. Additionally, aluminum plate’s resistance to corrosion adds to its longevity and appeal in outdoor or extreme environments.

Stainless Steel

Stainless steel, known for its durability and corrosion resistance, is ideal for powder coating applications. Its smooth surface ensures a high-quality, visually appealing finish. This makes it perfect for sectors that value both appearance and long-term durability, like architecture and consumer products.

Cold Rolled Steel

Cold rolled steel is favored for its smooth surface finish and structural strength, providing an excellent base for powder coating. It is versatile and cost-effective, making it suitable for various applications, from automotive parts to home appliances. Powder coating on cold rolled steel ensures durability and an enhanced visual appeal. Zemetal excels in using the benefits of cold rolled steel to deliver exceptional quality in every project.

Galvanized Steel

Galvanized steel, known for its strength and excellent weather resistance, is an ideal material for powder coating in outdoor or challenging environments. The zinc coating provides an extra layer of protection against rust, and when combined with powder coating, it significantly extends the material’s life. This makes it a reliable choice for outdoor structures and equipment.

Brass

Brass is a unique material for powder coating steel, offering both corrosion resistance and a distinctive appearance. Its natural golden color, combined with the versatility of powder coating, allows for creative and visually appealing applications. Brass is often used in decorative and architectural applications, where both aesthetics and durability are key considerations.

Painting Over Powder Coated Steel

Durability

Cost-Effectiveness

Application Efficiency

Environmental Considerations

Features and Benefits of Powder Coated Steel

Features of Powder Coated Steel

Chemical Resistance

UV Radiation Resistance

Sealant Qualities

Benefits of Powder Coated Steel

Long-Term Cost Efficiency

Versatility in Application

Eco-Friendly Nature

Application of Powder Coated Steel

Construction Sector

Home Appliances

Medical Equipment

Outdoor Furniture

4 Things to Consider When Choosing Powder Coated Steel Services

#1 Coating Thickness and Uniformity

#2 Turnaround Time and Production Capacity

#3 Certifications and Compliance with Industry Standards

#4 After-Sales Support and Warranty Policies

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us